Steel Car CompanyRobbins Cylindrical Steel Car Company

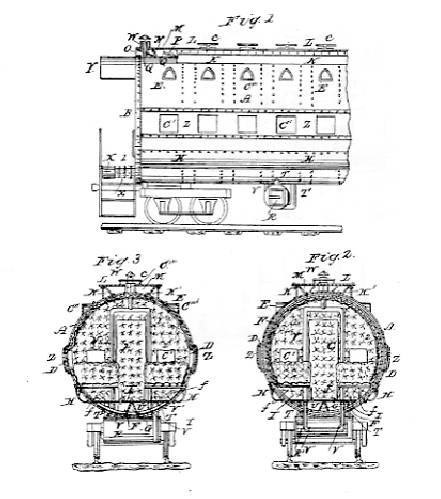

The first steel passenger car ever constructed was conceived by Edward Y. Robbins. Robbins was a sheet metal fabricator in Cincinnati who specialized in stove making. It is possible he started out trying to build a safe means of heating wooden railway cars, which were notoriously subject to fires begun by their coal-burning heating stoves. A significant part of his patent was for an external heating system that could have been applied to wooden cars as well as to his steel car. But Robbins’ thinking soon graduated to the idea of a fireproof car. His concept was unique: a car built as a self-supporting sheet-iron tube. (Actually, his patent called for it to be built of “thin plates of wrought-iron.”) Robbins was awarded patent no. 83,731 on 3 November 1868.

In The American Railroad Passenger Car, author John H. White, Jr. describes Robbins’ car thusly —

Robbins spent the next 20 years trying to get his car built. He first tried in July of 1869 in Cincinnati by putting on exhibition a large-scale model of his car. He found no backers, quite possibly due to the “Black Friday” gold panic that occurred two months later. He next tried to find backers in Great Britain, even taking out a British patent in another name, and presenting a model tailored to represent European ideas of rolling stock. But again, he found no interest. Nothing is known of his activities thereafter until 1884, when he founded the Robbins Cylindrical Steel Car Company in Boston, Massachusetts. Somehow he had found at least a little capital, and—since car builders of the day were either unwilling or unable to construct the steel car he designed—he had it built by the Atlantic Works, a shipbuilder in East Boston. The car was half finished by July of 1884. It had a 54'-0" body made of 3/8" steel bottom plates, with 3/16" thick side walls and a 1/8" thick roof. But before the 6" thick internal padding could be added, he ran out of money. And the stock market crash that had begun in May, with the ensuing depression, ensured that he would find no new backers.

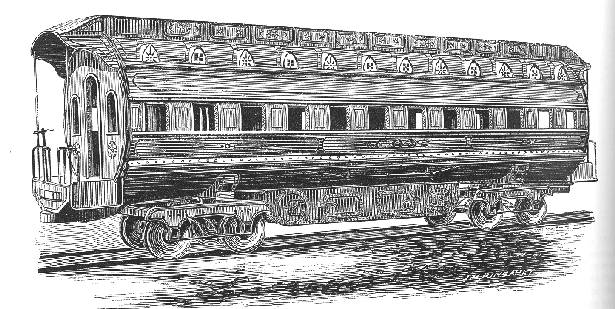

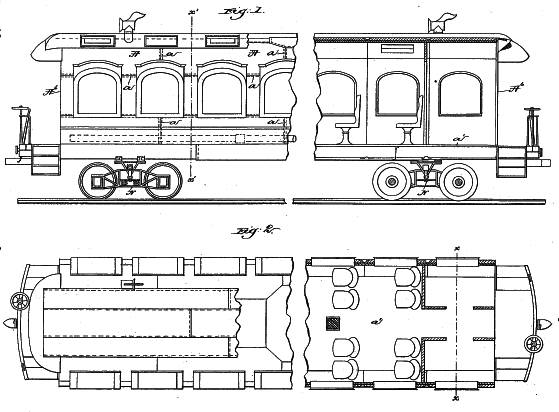

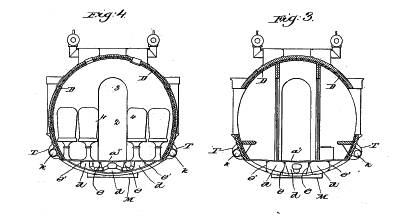

The assets of the Robbins Cylindrical Steel Car Company were acquired by Byron A. Atkinson (1854-19??), a well-to-do Boston furniture dealer, who had some background as a machinist, and as a furniture repairman. Presumably these assets consisted of nothing more than a patent and a half-finished car. To promote his cylindrical steel passenger car, Atkinson hired a Denver attorney named Henry D. Perky (1843-1906), who had quite a reputation for making money during times that ruined other businessmen. Their firm would be known as the Steel Car Company. After a false start, work resumed on the original car in the spring of 1887 at the repair shops of the Eastern Railroad. While it was being (hopefully) finished, Atkinson hired someone named Charles M. Smith [just try to research that name] to improve on Robbins’ design, which was incredibly ugly. Smith did so largely by adding sheet metal dormers to the cylindrical car body to allow much larger—although apparently still unopening—plate glass windows. Smith was granted a patent (no. 366,519) on his design 12 July 1887.

But work progressed slowly, and by 1889 it was obvious the Eastern railroad shops were unequal to the task. The unfinished original car was sent to the Laconia Car Company of New Hampshire where professional car builders could finish it. |