The new pilot beam has been fitted to the locomotive frame. This is temporary, but does help determine the positioning of the beam. The new pilot will have to be secured to this beam at a later date.

Category Archives: Western Coal & Coke #1 Status Updates

Crane Built to Assist with Restoration

Bob and Dave have built a crane to lift and position the front tube sheet for the WC&C #1. We test drove the crane last week.

Welding on the rear sheet continues as well as work on the frame and running gear. During Snow Train™ weekend, riveting the mud ring was started.

- New crane in engine house. Photo by Jim Connor.

- Work taking place on WC&C #1, February 28, 2007. Photo by Jim Connor.

Drilling Guide

Bob Ristow devised a drilling guide to ensure alignment of the replacement staybolts in the crownsheet patch. Here are a few pictures of Bob and Dave Lee drilling pilot holes for the staybolts.

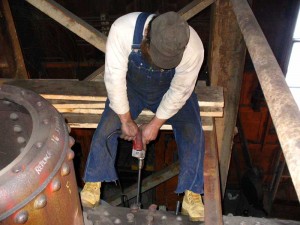

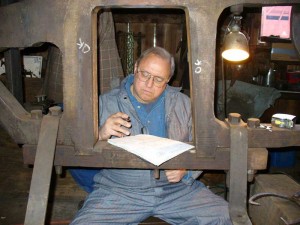

- Drilling pilot holes for staybolts.

- Drilling pilot holes for staybolts.

Measuring Frame Bolts and Tapping Boiler Stud Holes

On Friday, Pete Deets, Bob Ristow, Ron Kokemuller, and Jim Connor cleaned up around the boiler and other area’s in the shop. Pete, Bob and I spent some time on the project plan and timeline to make sure we are keeping everything happening in the order we should be.

On Saturday, Roger Hugg, Bob and I worked on measuring and documenting the frame and frame bolts so drawing can be made for replacements. Al Joyce worked on tapping boiler stud holes and installing them. This is a time consuming process because they are taper fit and each one must be fitted to the hole. Ron worked on enlarging the holes in the boiler mounting bracket that attach to the firebox.

Kyle, Jim Busse, Ed Ripp and Jim worked on the power car boiler. On Sunday they continued to install tubes in the power car.

On Sunday, Al continued on the stud work. Things are moving along well.

–Mike Wahl

Cleaning of Frame Completed

Bob and Dave continued to clean on the frame today and have it for the most part completed. There are a few spots that might need a little touching up. They also completed assembling the last set of shelves in the box car and started stocking them. Bob said that the box car is looking very nice inside and with the addition of the shelves it gives us a lot of room for storage of WCC#1 parts.