This is our 100th C&NW #1385 steam status update posted to our website and it is a momentous one! The locomotive’s new boiler has passed its hydrostatic test (a.k.a. hydro test). This test affirms the new boiler remains sealed with no leaks while at pressures well in excess of its designed operating pressure.

This test is conducted by filling the boiler to the point there is no (or practically no) air trapped in the boiler. Additional water is then pumped in until it reaches the designated test pressure – this can require as little as a few cups of water. Excluding the air allows the boiler and appurtenances to be safely tested for. If a leak appears the pressure quickly drops by relieving that cup or two of water.

To complete the test, the boiler is then left under pressure for a period of time. An inspector then checks to see if the pressure has dropped. If the pressure has gone down more than a few percentage points, it indicates a significant leak which must be tracked down and corrected. If the pressure does not see a drop by more than a few percentage points, it indicates there are no significant leaks and it passes the test.

The 300 PSI you see on the pressure gauge is 1 ½ times the designed maximum working pressure of the boiler. This is one standard benchmark percentage for testing and helps prove the boiler has a margin of safety when in use. The 1385’s boiler has been designed for a maximum allowable working pressure (MAWP) of 200 PSI with a minimum safety factor of four. This means the boiler is designed to withstand pressures of at least four times greater than the MAWP which you can see gives a sizable margin of safety when in use. The 200-pound pressure also marks a return to the R-1 class locomotives’ design pressure, meaning the engine will be restored to its original capabilities.

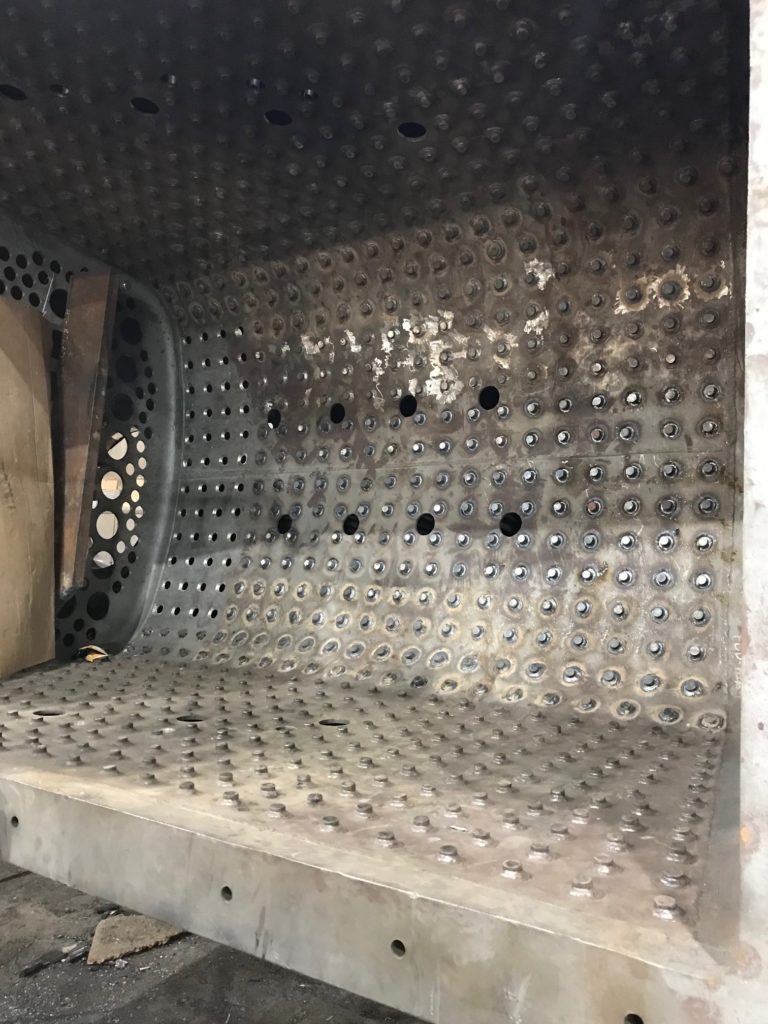

- C&NW 1385’s boiler being fed water as part of the boiler’s hydro test. Photo courtesy Continental Fabricators.

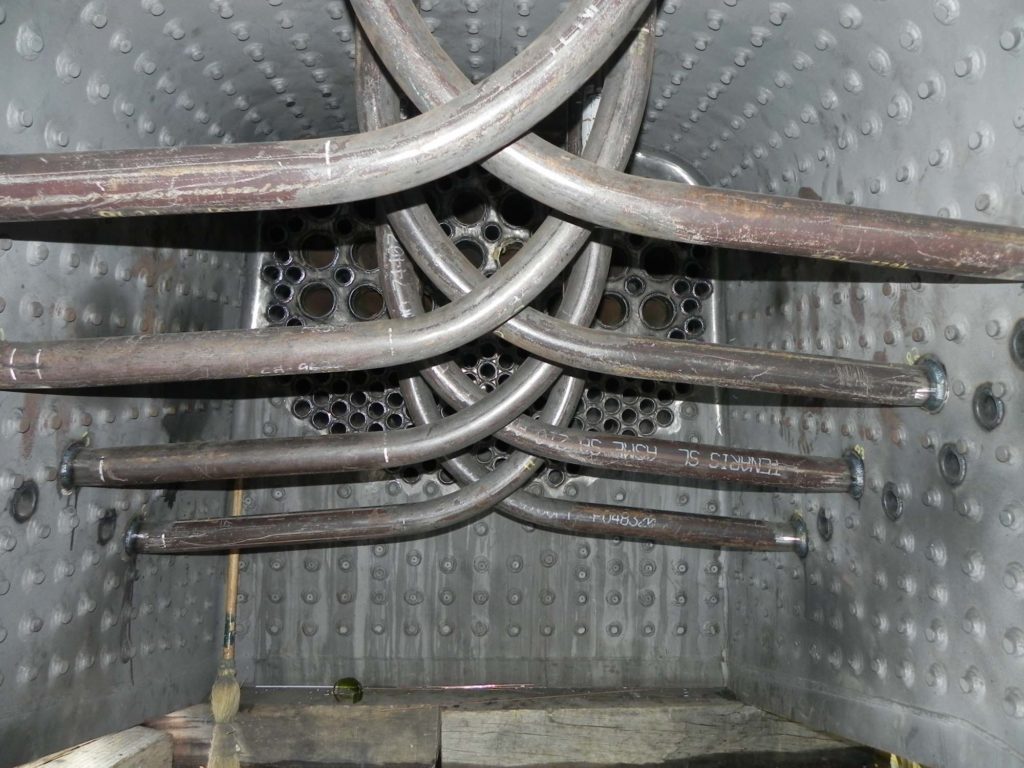

- Closer view of the finished tube work. Photo courtesy Continental Fabricators.

Up next: Prepare and attach the smokebox and paint the boiler exterior.