What a Snow TrainTM we had in the shop! Along with fairly cooperative weather and many fine guests we had probably the most successful weekend the mechanical department has seen in years. So many things were happening with so many people I did not get all the names. If I missed you somewhere, please let me know because I don’t want to short anyone and it takes the efforts of everyone to keep us going.

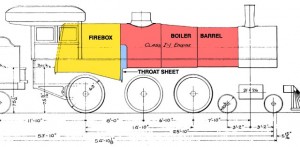

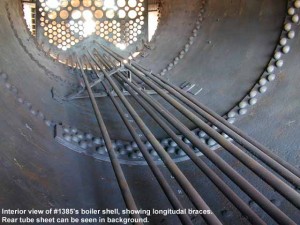

As of Friday, February 18, Becker Boiler finished the welding of the second course patch in the boiler. With that part done, we began preparations for the third course patch. As of this writing, the second course welding was X-rayed and no faults were found so that welded repair is finished.

By the end of Monday, February 21, the third course section was cut out and on the ground. By the end of Thursday, February 24, the replacement patch had been rough trimmed and most of the shaping and grinding on the boiler had been completed. Donations to cover Becker’s work have allowed us to make some very fast progress.

Friday of Snow Train (February 18) started on the rocky side with a few leaky tubes in the power car boiler but with the help of Dan Angles, the crew of Pat Campion, Johnny Winter, and Doug Crary, we were up and running in short order and the train was well warmed for the first trip out at noon.

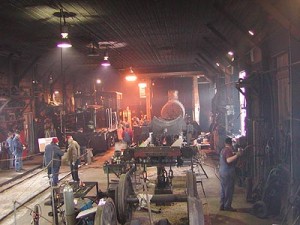

Bob Ristow showed up about 7:30am and after breakfast got to work in the shop to not only clean up but also to make ready for riveting. We were planning to try the novel idea of inviting the public in while we riveted the smokebox so there were considerations of safety, crowd control, a clean walking path, and earplugs to be worked out. Through the day Bob was helped by Doug Klitzke, Doug Crary, Kevin Pickar, Ken Ristow, Kelly Bauman, Dan Griffith, Jim Baker, Tim Weaver, and myself. Ken Ristow and another helper ground off staybolts in the boiler firebox in preparation for hammering. Hopefully those will get started on March 5.

Saturday dawned early and started well on the railroad with a breakfast prepared by Pat Campion and Tric Stankemuth. From there the shop crew and operations crew went to work. Here is where I’ll do my best to thank the operating crew that allowed the shop crew to work. In the power car were included: Pat Campion, Tim Weaver, Bryon Schumacher, Don Angles, Al Joyce, Bob Ristow, Ken Ristow, Robert Hasheider, Johnny Winter and probably a couple I’m missing. The operating crew including Greg Vertein, Jeff Bloohm, Lee Nelson, Jim Connor, Ken Hojnacki, Rick Peters, Doug Klitzkie, Steve Brist, Stan Searing, Ray Zilvitis and I am sure others. These folks are all part of the teamwork that makes Mid-Continent go.

Our riveting crew included Steve Seibel, Jason, Kevin Reihl, his dad, Tom Lines, Ed Ripp, Dave Schumacher, Bob Ristow, Mike Wahl, Tim Weaver, Dave Lee, Pat Campion, Kevin Pickar, Dave Bierman, Dan Griffith, and Doug Crary. We were able to get the front reinforcing ring attached to the edge of the smokebox and after lunch get half the seam welt on the top riveted in.

At the same time, our guests were invited in to observe what they could (mostly due to safety considerations) of the process and the tools of the job.

Further down Track 1 in the engine house, Rick Peters with the help of Bob Dischler welded up a crack in the hub of one of the Montreal’s drivers. That leaves one major crack left to be addressed and the drivers can then be sent out for machining. Rick termed this a major hurdle now overcome.

Lunch Saturday was provided by Evan’s mother and on Sunday by Sharon Crary. This is a great help not only for a needed break but much better use of time.

Sunday was again breakfast in the depot and back at riveting with a smaller crew. One addition was Stan Searing as lead docent to talk with the few patrons that braved the snowstorm that really wasn’t.

Other docents through the weekend included Pat Campion, Dave Schumacher, and Bob Dischler.

As with any weekend with so much going on, things tend to blur but we had so much fun we’ll be doing it again March 5 and possibly 6. We are also keeping the normal work time of March 12 and 13.

As I said in the opening if you didn’t see your name here please correct me because everyone involved deserves credit for the work done.