Mid-Continent Railway Museum’s steam restoration progress continues in a very noticeable way tomorrow (Oct. 17) with a crane coming to the museum to lift parts of two steam locomotives.

First, Saginaw Timber Company No. 2’s boiler will be lifted on to the frame/running gear. This comes after successful early tests of the running gear in the preceding weeks. Reassembly and further testing will continue in the coming months.

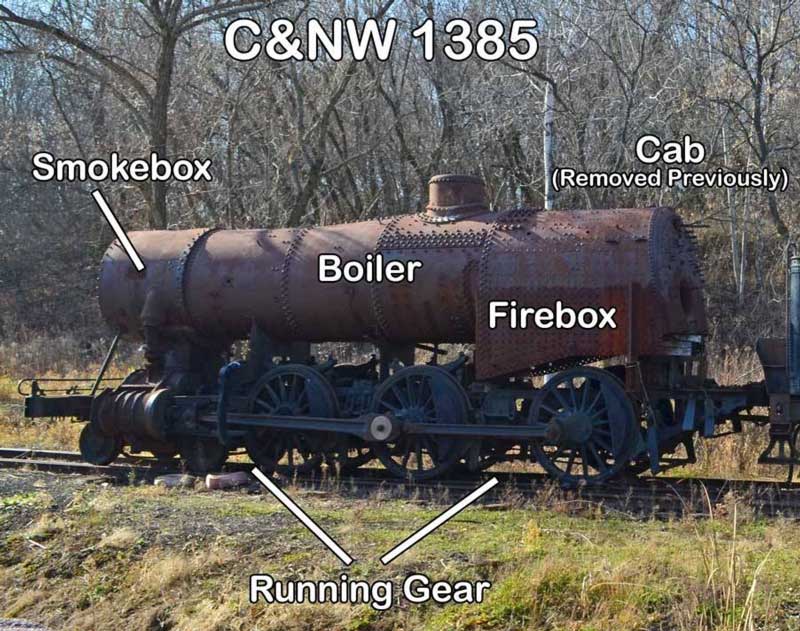

Next, the boiler (along with smokebox and firebox) from C&NW No. 1385 will be removed from its frame/running gear. The boiler will be set down in the space next to the Engine House being vacated by No. 2’s boiler.

This move marks a transition in the C&NW 1385 project from focusing on rebuilding the tender (which will be completed in the coming weeks) to working on the locomotive itself. The separation of the boiler from the frame/running gear will allow easier access to parts for restoration work and reverse engineering of replacement parts as the project moves forward.