President’s Message

2024 will mark 61 years at North Freedom Wisconsin for the Mid-Continent Railway Museum. I would like to thank you all for your help and support over this mild winter season. We have been busy at work both at the museum regarding management and maintenance/restoration. As you will read below the volunteers have been hard at work and we have made great positive progress. I would like to thank our volunteers and all our membership for their donations and time that has contributed to making Mid-Continent what it is today.

Buildings and Grounds

We have been cutting a lot of brush both by the Engine House, parking lot and by the turn table. We plan to have the whole area cleared between Coach Shed 2 and Storage Building #1. Then we will keep this area maintained in preparation for our turntable and future expansion.

The Fleet Shelter Building Commitee has been meeting regularly and we have had soil borings done in preparation of the foundation of the building. No, we are not building the building yet. We are in the discovery stage so we can bid on and permit the project.

We now have a plan to fix the post issue on the restoration building (Car Shop) and are working on getting bids from contractors on the project.

This summer we will be painting the outside of the restrooms and pavilion area so we will be looking for donations to cover the cost of the paint and volunteers to do the painting.

We will be changing the air conditioning out in the office building. It is 20 + years old and at the end of its life.

We will still be getting pricing for the Depot outside work, window repair, and Crossing Tower work.

We have ordered all brand-new wheels and axles for the Milwaukee Road #988. They should be in by the end of May. Also, we will be going to roller bearings. They have also been ordered and we have all the parts to make this conversion possible. The trucks are now waiting for these parts for final assembly.

The C&NW #1385 has its power reverse mounted and is getting ready for its hydro test that will be taking place in the next few months. Nearly all the holes have been drilled in the boiler for mounting appliances and preparation for final piping and transportation are being worked out now.

We will be doing handrail painting on the MCRY #7 and a wash and wax treatment to it to spruce it up this spring. If you want to get involved let me know. We will also be doing this on the 1256.

Spring Fling will be May 4th! Please come out and help get the museum ready for opening. Most department heads will be around and will be willing to talk about their departments and the work they do. You will then have the opportunity to work with them or move from department to department to experience what is done in that area. We also need your help with cleaning and preparation of opening day. Bob Anderson will be grilling lunch as he did last year. Please plan on being at the pavilion at 9:00 AM for introductions and announcements.

Help Needed

2017 Roof Work: We still need someone to head the repair and replacement of the Soo Line diner-lounge #2017 roof. This car is now living in Coach Shed #1 protected from the weather but is out of service. Not being able to offer dining experiences to the museum not only affects the income received by museum but also does not allow us to offer unique experiences to the public of dining on our railcars.

988 Project Manager: We need someone to head this project. The 988 is a unique Alco RSC-2 built for the Milwaukee Road in 1947.

Car Forman: We need someone to take charge of the rolling stock from light repair work to cleaning and brake repair.

If you can step up to any of these roles, please reach out to our office or me and we can talk more about the job description. Please consider a donation to one of the areas of the museum to continue positive progress. I look forward to seeing you at the museum in our 61st year. Thank you all for your help and support!

Update by Andy S.

Montana Western #31 Update

At the time of writing, the Winton engine has been disassembled to the point where cleaning and rebuilding has begun. While it has been determined that the engine needs an entire top end rebuild and two cylinders will require sleeves. It has also been decided that there will be no need to pull the crank or the camshaft as these have been tested and determined to be sound.

In addition, work has commenced on cleaning out water passages in the block as some were almost completely clogged with scale. Several parts, including three brand new cylinder heads, gaskets, rings, and other top end parts, have been pulled from our inventory by Ed R. They have been transferred to FMW employees in Middleton. Furthermore, we gave FMW the unusable water damaged cylinders sleeve that they say they can use as a pattern to make new ones. It has been decided that FMW will try to match the original engine paint as close as they can as no one has any information as to where Winton purchased its engine paint, or if the company is still in existence.

While the engine is out of the car body, several things need to be addressed: We would like to know the condition of the air compressor because if it has issues, now is the time to fix them. We know that the radiator has some problems, so we have to deal with that while the engine is not in the way. These are both big undertakings. Overall, a lot has been done, and much remains to be done if we are to meet our goal of restoration by its centennial in 2025.

Update by Rusty S.

Gift Shop Update

As of February 26, 2024, I have placed an order for 72 HO boxcar kits, expected to arrive in late March.

Our last custom car endeavor dates back to 2015. Unfortunately, following the release of that car, our supplier passed away, bringing an end to our custom car projects. Since then, we’ve reached out to various companies in pursuit of similar ventures. Recently, Track One has emerged as a viable option, offering to produce small quantities in multiple colors.

The HO car we’re currently working on will be produced in a batch of 72 pieces. We’re also exploring the possibility of producing a limited quantity of these cars in O scale as well!

Update by Jeff H.

Training Committee Update

By the time of this newsletter, the Steam/Diesel Training Committee will have submitted a Training Advancement Flowchart for Board approval.

It is our hope that the Board approves this visual that covers the necessary steps and minimum experience needed to advance from one craft to another. This is a huge step forward towards reactivating the vital component of advancement withing the Operating Department and also aims to attract new volunteers who can see the path to involvement at any level.

Our new conductor course starts the weekend of March 23rd/24th. Five students have met the qualifications and applied for advancement through the Training Officer. These students will be learning about delay reports, train registers, train orders and more throughout the weekend. Upon completion of the course, all five will be signing up for student trips with previously qualified conductors before taking a qualifying trip later this season.

Our new trainman class will take place over two weekends in April: the 6th/7th and the 20th/21st. Updated curriculum is still being finalized with the hope to add another group of student trainmen to the Operating Department by the start of the 2024 season.

The committee will continue to meet every two weeks to tackle additional training needs including updated daily inspection paperwork/checklists for our motive power as well as new versions of our fireman/engineer training manuals.

Update by Colin O.

Restoration Department Update

Volunteers in the Restoration Department have remained active over the winter months: working on projects at the museum, as well as at their home shops. The following is a summary of the recent progress made on several projects.

East Jordan & Southern #2

Pete, with the assistance of other volunteers, have continued to make progress restoring the interior of the car.

- Cut and installed the new T&G boards for the replica partition between the passenger and baggage sections.

- Made repairs to the flooring in the passenger section of the car.

- Continued sanding and varnishing the interior woodwork.

- Completed final prep work prior to staining and varnishing the clerestory lower edge trim.

- Selected paint for the lower crown moulding.

- Prepared painted lower headliners.

- Start construction of the seat bottom frames.

DSS&A DULUTH

- All new upper roof drip rails were made by Jerry F.

- The water damaged veneer on lower wall of the Smoking Room was removed.

- Mike completed the drawings for the missing doors in the car.

- Contracts have been placed for replicating the missing doors and the smoking-room veneer (lower east wall).

C&NW #1099 – Narrow gauge combine

Richard has been very active in reconstructing the wooden sills, beams and bolsters under the car. Richard has periodically been assisted by David P.

- (2) New side sills and body bolsters were made.

- The remnants of the old body bolsters were removed, and new body bolsters were cut, fit, and installed.

- A new body end beam on the south end of the car was cut, fit, and installed.

- New shiplap flooring has been made and Richard and David have begun installing the new subfloor.

Lake Superior & Ishpeming #64

- (5) Replacement windowsills made for the car by Jerry F.

- (26) New outer window stops (center and side posts) made for the car by Jack.

- All new window, corner post and door battens made by Jerry F.

- The water damaged interior walls around oval windows were removed.

- (22) New seat back frames were made for the car by Jack.

- Jack and Fred installed the new center window.

- Fred completed the repair to the NW corner post.

Great Northern A-22 Business Car

Larry has been working inside the car stripping the old shellac finish off the walls and partitions. He started in the north observation room and has been working his way south.

Chicago & Illinois Midland #90 Business Car

- Jerry M. made all new clerestory side wall moulding for the two staterooms.

- Jerry M. made a new swinging door for the aisle. He also stained and varnished two of the aisle’s swinging doors.

- Steve has been continuing to install new wiring in the car.

- Upcoming needs in the Restoration Department are volunteers for helping in the Car Shop during the MCRM Spring Fling session on May 4th. Volunteers are welcome to lend a hand on several projects in the Car Shop during May 3rd and May 5th in addition to Spring Fling on May 4th.

We are also looking for volunteers interested in participating in the upcoming “All Hands on Deck” session scheduled for June 26th-30th. For this session, we welcome volunteers that are interested in helping the Restoration Department make significant progress in the matter of a few days on a number of the active projects. Breakfast, lunch, and dinner will provided for all volunteers after their first day of participation in this session. In addition to the volunteer work, planned activities will be held each evening. Sign up for this session is required, and can be done by contacting Bill B.

Update by Bill B

Mechanical Department Update

Work completed:

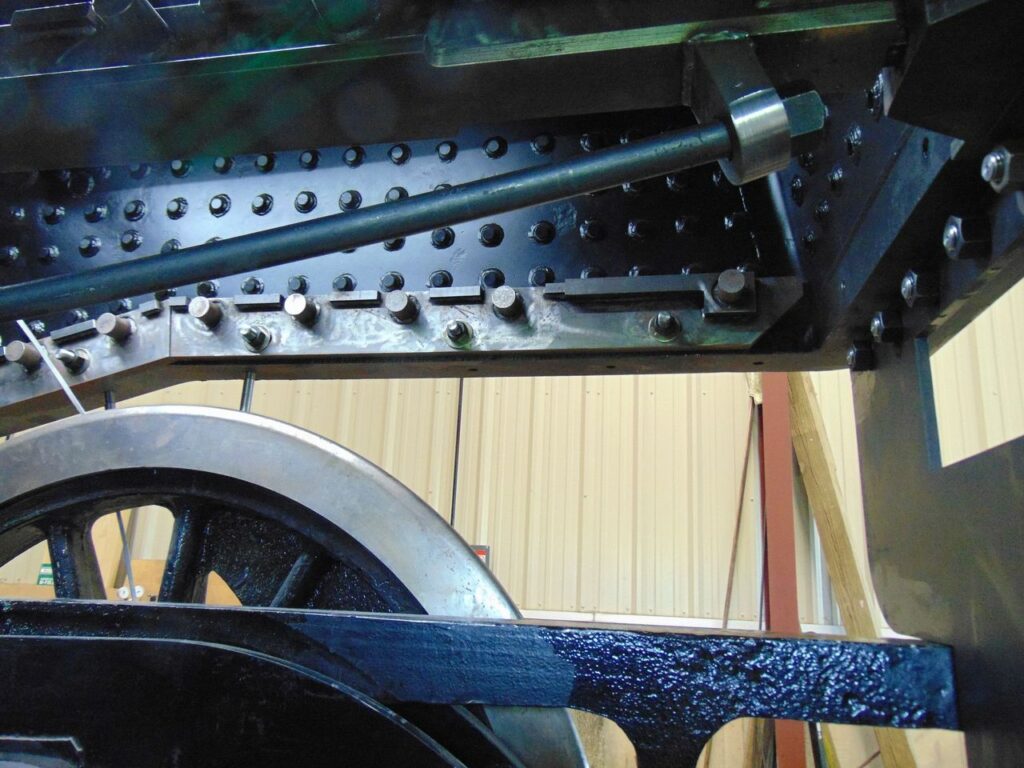

C&NW 1385 Tender

The wires for the rear headlight, marker lights and deck lights were pulled into the conduit that had already been mounted to the tender. The truck brake rigging had been reconfigured. There were some items that came up that will need to be addressed. This includes ordering different length brake levers to have the rigging line up properly. The braking force has already been calculated. This will be kept in mind while determining the truck lever dimensions.

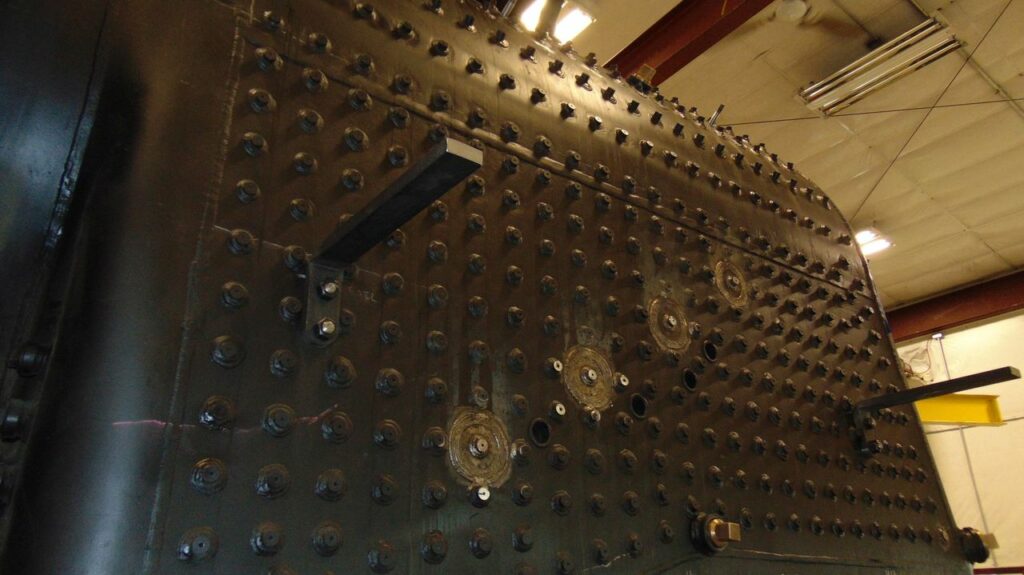

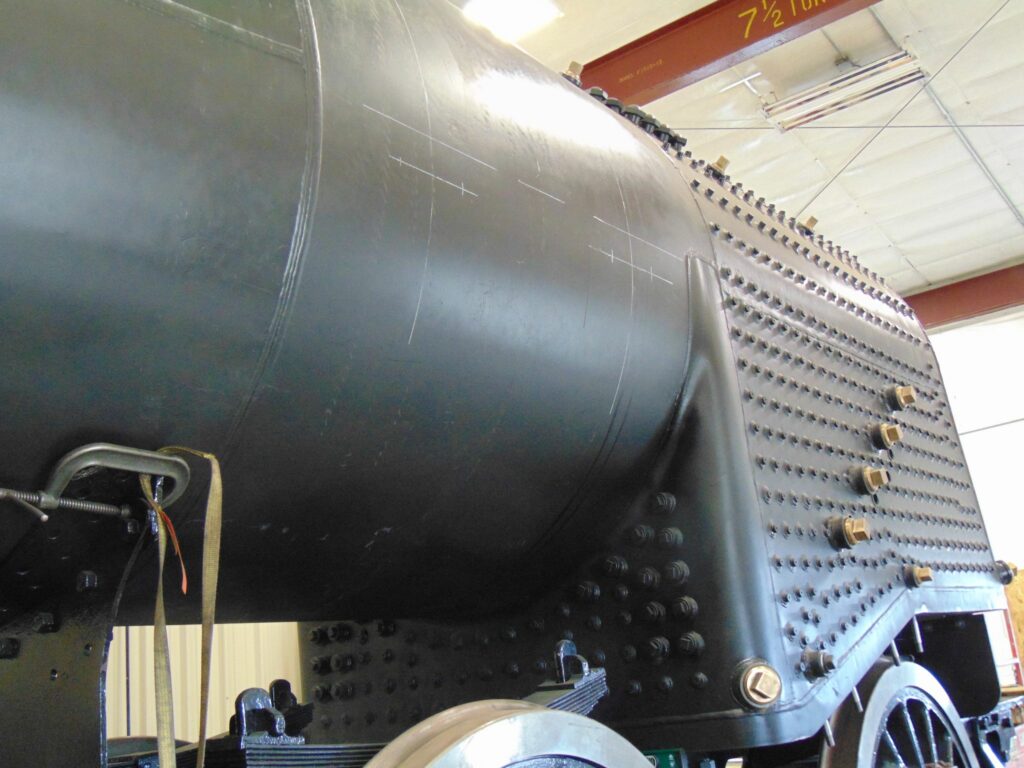

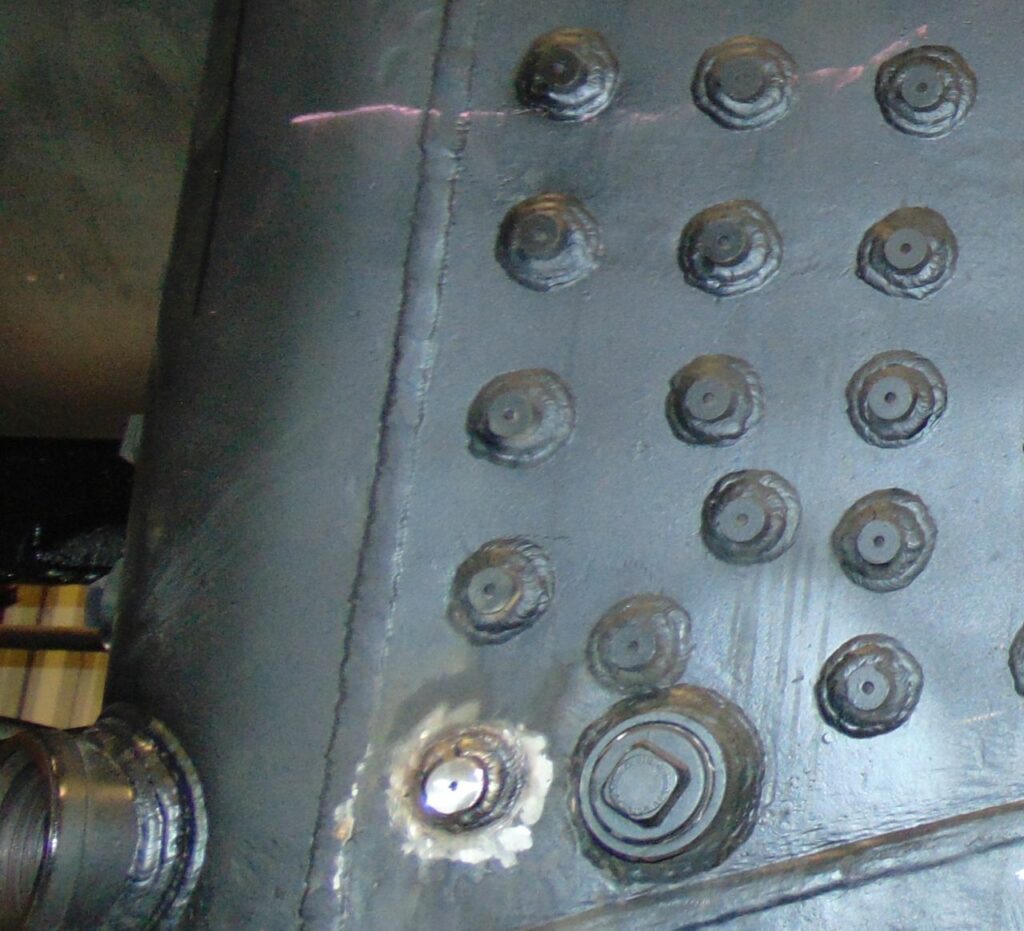

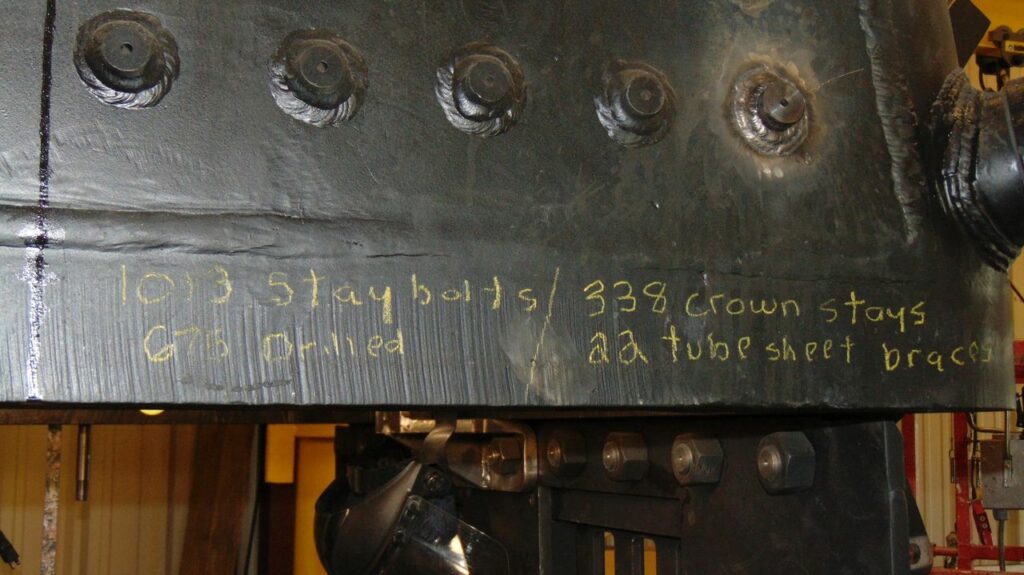

C&NW 1385 Locomotive

Almost every item that will be mounted to the boiler of our engine requires at least one more hole to be drilled into the boiler shell. In recent weeks the layout of where to drill some of those holes has been moving quickly. Among those completed are the holes for mounting the bell and the steps used to access and fill the sand dome. Item locations laid out and awaiting attention include brackets for the Brake Control stand, Reverser, Steam Gauge, Safety Valve and Cab turrets, and the Power Reverse Cylinder.

The runboards and handrails have been installed as well. Installing the runboards and handrails now is important for two reasons. First, every bracket, support, or stanchion is attached to the boiler with studs and each of those studs requires another hole in the boiler to be drilled and threaded. As part of the Federal Railroad Administration (FRA) inspections to bring a locomotive back into active service, the boiler is pressurized with water and every penetration of the boiler must be tight and with no leaks. This inspection using pressurized water is called the hydrostatic test and must be passed before we can fire the boiler for the initial steam tests. The other major reason for installing runboards and handrails now is it will make the remaining work on the top area of the boiler much easier. It will also make access much safer with a more stable platform to use.

General 1385 Update

We have also welcomed a new employee aboard the restoration project, TJ D. TJ comes with 20+ years of experience on locomotive rebuilding. He has worked for Kettle Moraine Railway and Mid-West Locomotive and Machine. TJ lives in the area and has winters off from his current career as an operating engineer. We look forward to his help and experience as we work to bring this project to completion.

MCRY 1256

An annual inspection has been started on the 1256. The brake cylinders were disassembled, cleaned, inspected, and greased. The brake cylinder travel was adjusted after this. Some of the lower main generator brushes that were worn have been changed out.

MCRY 7

A battery maintainer has been temporarily wired into the batteries of the 7. This will ensure that the batteries are fully charged so that they do not freeze during the cold months. There are maintainers on hand to be installed on the 1256 and the 1001.

DLW 425

The electrical system on the 425 has been inspected and a work scope has been put together to correct some issues. This will include replacing some old wiring in existing conduit.

DM&IR C-74

The brake cylinder was disassembled, cleaned, inspected and greased. The conductor’s valve in the cupula has been changed out with a quarter turn valve to repair the major air leak. A preliminary leakage test was performed. The car should now pass the leakage test during its annual brake test.

Work Coming Up:

C&NW 1385 Tender

Work to continue with the brake rigging. Prepare the cistern for blasting and application of coating. Continue working on installation of fixtures for the lighting.

MCRY 1256

Continue the annual inspection work. Plan out and install the battery maintainer.

MCRY 7

Install the brake control valves when they arrive. Test brake system.

Operating Fleet

Last year we started performing a single car test on the braking system of our operating fleet. We are waiting for the single car test device to arrive back from the shop where it will be requalified. Once this is back, we will start going through and performing the single car test on our operating fleet. We will also be applying lubricating disks in the bolsters of the operating fleet as they cycle through the Engine House for their single car test. This will require the car to be jacked up far enough to place the disk in the bolster bowl.

We can always use help in the Engine House. I will send out updates for work sessions to the member’s discussion board and via email. If you would like to be added to this email list, pass along your address to the office indicating that you would like to be added to the Mechanical Department email list.

Update by Ed R.

Engineering Department Update

Hello All,

It’s been a very interesting and productive winter here at Mid-Continent. As you all no doubt have seen, we’ve managed to acquire 90 lb. rail from the Wisconsin & Southern Railroad. Knapp Railroad Builders has been awarded a bid to lay out, or pedal out, the “new“ rail In preparation for installation. As well as sorting and stacking the excess rail and materials for storage. We are working on drawing up a bid package for the installation of this rail into the main, hopefully for this fall. So keep your eyes open for future announcements regarding that.

Also, this winter Jim B. and his group have been busy cutting down nuisance trees along our line. They have opened up the tree cover thru a significant stretch of Wood Curve to enhance our riders’ views. As well they’ve also cut down trees that have and potentially could strike the train. We will also be looking at cutting up trees that have fallen due to excessive winds that are laying along the tracks, but clear of the trains in the coming months before startup.

As I said it’s been a busy/interesting winter. I’ll plan on posting any potential Engineering work days/sessions on the member forum so keep your eyes peeled for any updates.

Update by Nick V.

Tree and Brush Clearing Update

Weed spraying takes place twice a year and last year was the first for brush spraying. This is the best way to keep vegetation from taking over, but it only reaches so far. Most of us have ridden the train year to year and have seen the downed trees from storms, dead trees from disease, and thick brush taking over. Our right of way has become littered with a lot of flammable debris. With the eventual return of steam, a few members and I have set out to address this matter. We are the newly formed ‘Line View Improvement Crew.’ The first area we are nearing completion on is Wood Curve. This spot offers our passengers a view of the old farm house to the east and it’s a good place to take a picture of the train from Hwy PF.

There is A LOT MORE TO DO and we need MORE HELP! This will be an on going year round project weather permitting. All work is ground work no aerial. We work in pairs for safety. Cutting and piling brush is the majority of the work. We recommend wearing long pants and a long sleeve shirt. As well as, gloves, safety goggles, and bug repellant. For more details please call Jim B.

Update by Jim B.

Dining Train Update

Since the last article in the December 15, 2023, Mid-Continent News, members of the Dining Services Department helped with the Holiday Flyer Trains on December 2, 2023. Because both trains were sold out, the members had to prepare the hot chocolate passengers in three 100-cup coffee makers and four 30-Cup coffeemakers. Once each of the trains departed the depot, the members had to pour, cap, and deliver the hot chocolate to the passenger cars to be handed out to the passengers. The 4:00 PM train served 216 cups of hot chocolate and the 5:30 PM train served 223 cups of hot chocolate. All the drinks were out and served to the passengers before the trains reached the quarry. Needless to say, the members did a lot of pouring, caping, and delivering of drinks in a short period of time.

The following members assisted on the Flyer Trains: Jay S., Chuck P., Colleen P., Jim B., Gary B., Tom P., Ed R., Tom H., Robert D., Adam Cl., Grant H., Jeff L., Jamie S., David, S., Andy S., and Jeff H.

Bad News – The 2017 has sustained roof damage and will not be able to be used for dining trains until the roof is repaired. Since the 2017 seating is 55% of the total dining seating, the decision was made to cancel future dining trains until the roof is repaired. So, there will be no dining trains for 2024.

Good News – Because of the success of the Holiday Flyer Trains in December of 2023, a decision was made to run additional Flyer Trains during the 2024 train season. Unlike traditional dining trains, the Flyer Trains take place aboard Mid-Continent’s coach cars. The Operating Department and the Dining Services Department are looking at running additional Flyer Trains on the 6th of July – called the “Freedom Flyer” featuring popcorn and fruit punch, 24th of August – called the “Root Beer Float Flyer” featuring root beer floats, and 19th of October – called the “Harvest Flyer” featuring donuts and hot cider. The trains are scheduled to run at 5:00 PM on those dates, with the possibility of an additional train at 6:30 PM if the first train is sold out. The Holiday Flyer will be returning on the 7th of December with trains scheduled at 4:00 PM and 5:30 PM with hot chocolate.

Since the museum will be running the additional Flyer Trains, the Dining Services Department will be looking for additional volunteers to work on these trains. If any member of the museum is interested in serving on the Flyer Trains, please contact Jeff H. No experience is necessary, and we do on-the-job training.

In addition, the Dining Services Department is still looking for a Superintendent of Dining Services for next year. If anyone is interested in serving as Superintendent of Dining Services, please contact the office.

Update by Jeff H.

D&R #9 Update

Happy 2024 to all our followers and generous donors! The D&R #9 crew appreciates all your support. The D&R #9 cosmetic restoration began in the Fall 2020. Much has been accomplished, but there is a lot more to do.

A brief history of the D&R #9 begins back in 1884 when the Baldwin Locomotive Works constructed the locomotive as New Orleans & North Eastern. It received a new boiler in 1904. NO&NE sold the locomotive to a surplus dealer in 1917. The locomotive was purchased by the Dardanelle & Russellville in Arkansas and was renumbered to #9. The Mid-Continent Railway Museum purchased the locomotive in 1963 and served as one of Mid-Continents daily operation locomotives on and off until 1991 when it was removed from service because of boiler issues. The D&R #9 is the oldest locomotive on the property.

The locomotive was stored as inoperable until 2020. During the Fall of 2020, a small group of Mid-Continent volunteers along with MC’s Restoration Department decided to cosmetically restore the locomotive to preserve it until a time when she gets her turn in the shop for an operational restoration. The project is led by 10-year-old (as of 2020) Fletcher R. along with his father Jason.

Today, Fletchers Crew is proudly sharing the progress which has been made over the past 3 years on the D&R #9. The D&R #9 Restoration Project initially raised $9,999 through our generous donors to begin the project. But this was primarily used to cosmetically restore the tender. The tender is the “car” that is directly connected to the locomotive to carry fuel and water for its operation. In the case of the D&R #9, the tender carries 5 tons of coal for fuel and 3500 gals of water for the boiler. The tender is now complete minus the headlight and foot boards on the rear.

Now it is time to focus on the locomotive itself. We are dedicating the 2024 season to the “Year of the Cab.” There is much work to do in the cab. There is some wood rot in the interior of the cab. The roof hatches leak, cab floorboards need to be replaced, seat boxes repaired and re-upholstered, and all fixtures in the cab need to be cleaned and painted. The exterior of the cab will then need to be sandblasted and painted just as the tender was. Additionally, depending on volunteer “man” power, running gear will need to be cleaned and prepped for paint. As always, Fletchers crew welcomes ALL volunteers! If you enjoy learning and having fun, that’s all the skill you need!

For our second fundraiser, we are again setting our goal at $9,999. Through your generous donations we can attain this goal. We appreciate any donation you can make towards the project. Every little bit helps! Without your generosity, the wheels of progress will grind to a stop. Fletcher’s “Crew” is dedicated to bringing the project to completion. We will work hard, and we are committed to spending your donations wisely and frugally. Thank you for your support! We cannot do this without you!

Update by the D&R #9 Crew

Meet a Member

For this “Meet A Member” entry, I would like to introduce Adam C! Adam is one of our youngest volunteers at Mid-Continent and the newest addition to the Board of Directors. He is extremely active in our Operations Department and Switching Crew. His intense passion for railroading has been a longstanding family tradition of sorts. It all started with his grandfather, who worked odd jobs as a mechanic, switching between cars and various locomotive shops. His grandpa would often take Adam’s father out on railfanning trips across the United States. Whether it be out west, watching the great C&NW coal trains in Wyoming, or spending days in Wisconsin Rapids, riding in the cab of the GBW Alcos. Needless to say, this passion did not waver once Adam was born. Adam has been told that his first railfanning trip happened when he was just six months old – (probably) making him the youngest railfan to ever exist. His father had worked in the industrial train yards of the Minnesota Commercial Railway for 17 years, where switching cars was a day-to-day norm. Adam joined his father inside the cab at a young age, some days inquiring to watch the switching from the ground. Thus, sparking his lifelong interest.

Even though the cards didn’t play out for Adam to have a career in trains, he happened upon Mid-Continent in 2021 when looking for volunteer opportunities. When I asked Adam what drew him to Mid-Continent, he said that when he visited, he was instantly captivated by his experience. This place filled the gap and was everything he was looking for. He knew from that point forward that he wanted, no, he NEEDED to be a trainman. After successfully getting into the trainman program, he has been volunteering ever since.

This naturally led me to inquire about Adam’s favorite memory during his time as a member, and he eagerly recounted his first experience volunteering on the Santa Express. Adam’s adventure started as he completed his brake test and made his way to the front of the train. His account through each car resembled the descriptions in a Tolkien novel, with the festive atmosphere of the holiday season palpable as he moved from the coach cars to the power car. Amidst the warmth of the coal-fired heat and the cheerful melodies playing over the speakers, Adam couldn’t help but notice the joyous expressions of both the riders and the volunteers who kept the train running smoothly. His adventure concluded in the business car, where he found a calm conclusion to the bustling journey. Adam holds a deep affection for the unique ambiance of the Santa Express and eagerly looks forward to continuing his volunteering efforts during this special event.

The final question I had asked Adam made me swell with pride for the museum. I had inquired what the museum meant to him personally, and how he sees it evolving through the coming years. He had replied that there’s a lot of exciting ideas floating around that he would love to see implemented eventually. He appreciates the shared commitment to excellence among the museum staff and members, expressing confidence in our ability to overcome any challenges as a team. Adam praised the museum for its focus on member ownership, highlighting the inclusivity of our decision-making process where everyone’s voice is heard, and challenges are met with a collaborative spirit rather than a simple rejection. One particular statement from Adam resonated with me: “This is the kind of place someone dreams about.” Mentioning that he often finds himself dreaming of this place, quite literally, underscoring the deep connection and pride he feels towards the museum. To me, this encapsulates the essence of Mid-Continent’s mission, and I can’t wait to see what’s in store.

Written by Becca M.