The Steam Readiness team is gearing up for the return of the C&NW 1385 next year. In late July an order was placed for a new water pump which is to be installed at the end of the line at Quartzite Lake. For the foreseeable future, it will serve as the museum’s primary locomotive water supply source. The water tower at North Freedom is not presently able to hold water due to deterioration of the wooden tank, plus it used to be fed by the Baraboo River, but the river’s poor water quality makes it unsuitable for future use. The museum’s well is only low capacity and is just adequate to keep up with restroom usage.

The new pump at Quartzite Lake is rated at 300 gallons per minute (the 1385’s rebuilt tender has a capacity of 7,500 gallons). A 2-1/2 inch fire hose will be utilized to get the water from the pump to a bottom-feed port built into the tender tank. This will eliminate the need for crew members to climb on top of the tender tank to take on water using the old water column—an important safety consideration given that many Mid-Continent volunteers are retirees and may not be as agile as the typical steam crews of yesteryear.

The 1385’s boiler progress continues to move forward at a steady pace. Initial assembly of some of the fundamental components identified several minor discrepancies. It was noticed that a few pieces of the raw material did not conform to the design tolerances. While the discrepancies did nothing to jeopardize the boilers construction, they did warrant an extensive review of the computations and detail drawings that support the firebox. This review was completed and addressed all of the issues adequately.

Continental Fabricators has spent the following weeks updating their engineering data to accommodate these revisions. This has caused some delay in the assembly of the boiler but fortunately no alterations are necessary. The task force members, working in conjunction with Continental’s Engineering team are nearing completion of this task. As soon as the data streams are re-aligned, work on assembling the boiler will resume. A new fabrication timeline will be developed as soon as work is ready to be resumed.

Meanwhile, Steve Roudebush and company at SPEC Machine have stayed busy working on other components of the locomotive. The photos and captions that follow highlight the recent work taking place at SPEC Machine’s shop in Middleton, Wisconsin.

- Work on refurbishing the valve gear is mostly complete and installed. Unpainted parts used for mounting the brake cylinder can be seen being test fit and readied for installation after painting.

- Because of their placement within the frame, the eccentrics are notoriously difficult to access [and photograph], but are seen installed on the main driving axle in the lower center portion of this photo.

- The Stephenson gear’s link and link block (upper center of image) are in the process of being fabricated new because the original was worn through the heat treating.

- The brake head mold was made by sacrificing one of the originals and welding up the worn areas to create the desired shape.

- New return springs for the brake cylinder were found in Mid‑Continent’s inventory and soda blasted. These will replace the existing springs which were worn. Properly compressing the springs is one of the immediate tasks ahead.

- A new cylinder lever shaft ready to be cut and drilled to replace the original.

- Brand new freshly milled brake equalizers lay on a pallet ready for painting.

- Brake connecting components ready for painting and a box of new pins ready to connect them all.

- Locomotive electrical diagrams hang on the shop wall in preparation for MCRM volunteer and professional industrial electrician Allen Hinke to begin wiring the cab.

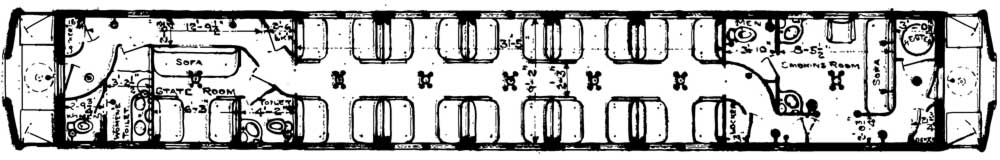

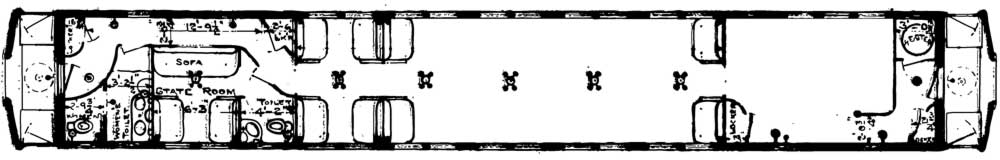

- This is SPEC Machine’s new shop bay, built specifically with 1385’s clearance needs in mind. The running gear will be moved here in advance of the boiler’s arrival.

Report by Jeffrey Lentz with contributions from Brett Morley and Steve Roudebush.