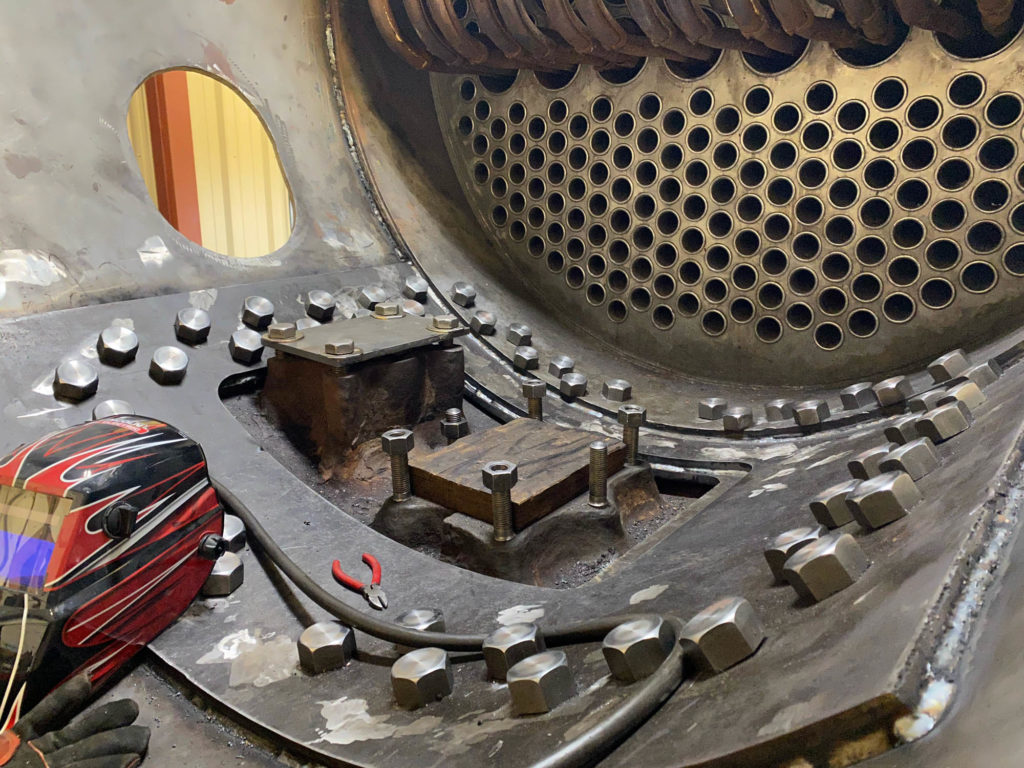

Mid-Continent Railway Museum has announced plans to begin the cosmetic restoration of the Dardanelle & Russellville #9 steam locomotive starting in Spring 2021. The restoration will be more than just slapping on a new coat of paint. It will involve a number of steps, each involving expenses: grinding, stripping, and blasting of the locomotive to provide a clean, rust-free surface, repair/replacement of deteriorated wood, sheet metal, and other custom components, primer, paint, and associated supplies, and finally the creation of interpretive display materials.

To complete this project, your help will be needed! Mid-Continent has begun fundraising for the project, with a goal of raising $9,999 to support the #9. If you wish to see Mid-Continent’s oldest locomotive made beautiful and ready for public display once again, please consider making a contribution today.

Mid-Continent Railway Museum is a 501(c)(3) non-profit. All donations are 100% tax-deductible and a donation acknowledgment letter will be provided.

If you wish to become a project volunteer, please send an email to inquiries@midcontinent.org. Volunteer sessions are anticipated to begin in spring 2021.

Fundraising progress thermometer last updated: 03/19/2021.

Fundraising Update 3/19/2021:

Mission accomplished! Our fundraising goal for this project has been achieved. Thank you to everyone that has contributed.