Tom G. of Continental Fabricators kindly supplied Mid-Continent Railway Museum with this photo of C&NW 1385’s boiler. The photo was taken on April 17, 2019, and shows the boiler barrel in position as it is readied to be joined to the firebox. Work on the boiler is taking place at the Continental Fabricator’s shop in St. Louis, Missouri. When completed, the boiler will be delivered to Wisconsin and be set on the C&NW 1385’s overhauled frame.

2019 Trainman Class

Join the Mid-Continent Railway Operating Crew

Here is a unique opportunity to be a part of our working railroad by joining the Mid-Continent Railway Museum Operating Department. We are now accepting applications for our training school beginning which starts on April 13, 2019.

What does a trainman do?

Note: The term ‘trainman’ is the historical job title used by railroads of the era and thus is used at Mid-Continent. Women can and do serve as trainmen as well and are encouraged to participate in all facets of museum operations.

Trainmen work alongside the conductor, fireman, and engineer to operate demonstration train rides for museum visitors. The position includes physical aspects: coupling/uncoupling cars, guiding train movements, inspecting cars, etc. It also includes social aspects: speaking with museum visitors and passengers, answering questions, and serving as a public face of the museum.

What is taught in the class?

During your four day training (two weekends) you’ll learn the basic operating and safety rules in use by Mid-Continent Railway during classroom sessions and then working outside with the museum’s equipment during the hands-on portion.

Eligibility requirements

Only Mid-Continent Railway Museum members ages 18 and above and in good standing are eligible. (Learn about becoming a member). Four days of in-classroom and on-site training is required followed by individually scheduled days of job shadowing and a final qualifying test. Persons qualified on other railroads are not exempted from the required training. Limited class space is available and signup is offered on a first-come, first-serve basis.

Keep in mind that some aspects will require you to be physically capable of – but not limited to – performing such tasks as throwing switches, replacing coupler knuckles, minor rolling stock maintenance, climbing onto and off of equipment, and working in all types of weather conditions.

Do I have to know a great deal about trains and railroad history to enroll?

What you need to know about train operations will be taught to you in class. As for general railroad and railroad history knowledge, there are no prerequisites or tests. You will learn a lot just by going through the class and student trips and being around fellow volunteers. Your instructors may have suggested reading materials for you as well.

How frequently is the class offered?

The trainman class is offered once per year, each spring.

Is there a class to become a conductor or locomotive engineer?

Yes, but all new train crew volunteers are required to first start as a trainman.

How much does the class cost?

The cost to attend is free, but you will need to equip yourself with the proper clothing and purchase a rule book which will be explained in the trainee’s invitation email.

What is the time commitment?

The training program last four days (April 13-14 and May 4-5, 8 AM-5 PM each day). This must be followed up by completing three-to-four of student trips prior to the end of the operating season. Student trips are done on your schedule and can be completed during most any day that trains are operating.

In subsequent years, volunteers are expected to volunteer in train crew service a minimum of four days each year to remain qualified. Every third year train crew members must also attend a one-day refresher and recertification test.

What if I am not a Mid-Continent Railway Museum member?

Museum membership is open to anyone and starts at $40.00 per year. For more information on membership, see the Join Us page.

How do I sign up for the class or find out more information?

Simply contact the Mid-Continent Railway Museum office at 608-522-4261 or inquiries@midcontinent.org to verify your museum membership status (or sign up to be a new member) and then be put in contact with MCRM’s Operating Department training officer.

1385 Firebox and Wrapper Assembly

Our previous post provided a tour of the Continental Fabricators facility where the brand new boiler C&NW #1385 boiler is being constructed. In this post, 1385 Task Force member Pete Deets shares his photos taken of the 1385 boiler during their shop tour in late February.

At the end of the previous post, I thought I spied something familiar. Could it be our own beloved R-1 in the distance?

Indeed, here are the pieces of the new vessel.

This is actually an assembly table embedded in the shop floor which gives the boilermakers a stable, flat surface to work from. The mudring/firebox assembly is mounted to standoffs on the I beams and is set up to be level and square. With the foundation ring level and square the rest of the boiler assembly can be indexed off that so there won’t be twists and turns where we don’t want them. The boiler barrel courses/smokebox assembly is on the I beams ahead of the firebox. In the photo above Tyler R. of SPEC Machine inspects the wrapper assembly. In the photo below Tyler and Steve R. talk over the boiler with Tom G. of Continental.

From the other side of the assembly table we’re looking into the smokebox at the front tubesheet with the firebox assembly setting beside it. The small holes are 2-inch diameter for the tubes and the larger holes are 5 inches for the superheater flues. The largest hole is for the dry pipe which will carry the steam from the throttle inside the steam dome of the boiler into the superheater header which lives in the smokebox. After traveling through the superheater units the steam will leave the high temperature side of the superheater header and head down the branch pipes to the valves and cylinders to make everything move.

The above picture is looking through the dry pipe hole at the rear tubesheet on the firebox assembly. It won’t be too long before these are joined together.

Here is a good look at the backhead portion of the wrapper assembly. You can see temporary “strongback” braces that are welded on here as on many of the other parts. These are to minimize warping from the heat of the welding process and are used to keep flat sheets flat and round pieces round.

This is a look inside the wrapper assembly at the permanent braces that are attached between the wrapper shell and the backhead. The Continental staff spent several weeks laying out and fitting the braces because there will be staybolts installed in every one of the small holes in the wrapper. The stays will tie the firebox and wrapper sheet together as the steam inside tries to push them apart. There must be a specified clearance or space between the braces and staybolts so they can’t rub.

Here is a closer look at a pair of stays that required a slight bit of adjustment.

This is a look at one corner of the mudring/firebox. The tab at the left of the photo is tacked in place to help locate the wrapper as it is lowered onto the mudring. The U-shaped pieces of wire will be used as spacers between the wrapper and mudring to maintain the required gap between them as part of the full penetration welding process. The written welding procedure states a specified gap must be maintained between the parts and that gap is filled with the welding rod in what is called the “root pass” of the weld. The wrapper will first be tacked into place with several small welds and the spacers will then be removed to allow the procedure to continue.

Here is a little closer look at the finished full penetration weld joining the firebox to the mudring.

This is the bottom of the wrapper assembly where it will be welded to the mudring. The edge is ground off at an angle or beveled to allow the welder to reach to the very inside edge of where the wrapper and mudring will meet. This is vital to allow the “root pass” to join the innermost surfaces of the wrapper to the mudring and then layers of weld will be built up on top of the root to the full thickness of the wrapper sheet. This way the joint between the pieces can be considered as strong as the pieces that are joined together.

This is looking up at the center rear of the top of the inside of the firebox. The 2 pieces of the firebox join the door sheet and the weld line runs down the centerline of the boiler. You can also see how the staybolt holes are beveled like the bottom of the wrapper was to allow for the full penetration weld.

Here’s one last shot of Tyler, Steve & Tom.

A few days after the visit, Tom from Continental Fabricator’s sent over a photo he took on March 4th showing further progress on the firebox/wrapper assembly.

Flexible Staybolt Design and a Boiler Factory Tour

Photos and text by Pete Deets

Staybolt Update

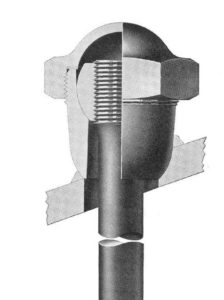

No, this is not a fleet of UFO’s lined up at SPEC Machine. These are the caps for the latest batch of flexible staybolts being made for the 1385.

The caps and sleeves shown (above) and the staybolt itself is completed when a ball end (below left) is threaded onto the bolt and the bolt is placed into the sleeve (below right).

Below is a comparison of the two types.

You may wonder why we need 2 types of flexi’s. That is because we have to allow for support of curved as well as flat surfaces. This illustration from the 1938 Flannery Staybolt Catalog shows how the first batch of staybolts will be applied. This is the UW style and is designed to be used where the staybolt will be going through the supported sheet at close to a right angle and the inside and outside sheets are very close to parallel. The flexible staybolts on the throat sheet at the front corners of the firebox will utilize the UW style.

The latest batch is the WR style which is designed to be applied where the inside and outside sheets curve at different rates and do not run parallel. This is the situation near the top of the wrapper sheet and firebox. Because the top of the firebox (the crownsheet) is rolled in a tighter radius than the wrapper sheet and the rigid end of the staybolt needs to be square to the sheet it is attached to the flexible end goes through its’ sheet at some angle.

- UW style flexible staybolt. Illustration from 1938 Flannery Staybolt Catalog.

- WR style flexible staybolt. Illustration from 1938 Flannery Staybolt Catalog.

All these parts are coming together and will be forming a boiler very soon.

A Look Inside the Continental Fabricators Factory

I took a quick trip with Steve & Tyler Roudebush of SPEC Machine to deliver a palette of parts to Continental Fabricating in St. Louis as well as inspect the progress on the new boiler for 1385. More photos and details about the boiler will be posted later but I wanted to share a few shots of Continental’s shop. I hope this will give folks a feel for the size of operation building our vessel.

- Continental keeps on hand over a million pounds of certified material stocks.

- A few pieces in process.

- This plate roller is designed to shape steel plates 6 inches thick. It will accept a flat plate and roll it into a round barrel shape.

- Radial arm drill. Look closely and you’ll see a worker inside the vessel that’s sitting on the radial arm drill.

- The 20 x 20 x 80 ft heat treat oven.

- A small vertical lathe.

- Steve, Tyler of SPEC Machine and Tom G. of Continentral.

- Some slightly larger machines.

- Incoming material including the steam dome cover for the 1385. Also a small shear and press in the background.

- A slightly larger press.

1385 Project in BIC Magazine

Continental Fabricators was recently highlighted in Business & Industry Connection magazine. In discussing current projects at Continental, boiler fabrication for US Sugar #148 and Mid-Continent’s own C&NW #1385 were highlighted as the type of specialty projects Continental is capable of tackling.

You can check out the digital edition of the magazine, which includes a photo of 1385’s boiler.

BIC Magazine’s circulation includes industry managers and executives in the refining/petrochemical, drilling, pipeline, marine, terminal, pulp and paper, power generation and heavy construction industries.