With the C&NW 1385’s new boiler fabrication just completed, Mid-Continent Railway Museum wasted no time getting it on the road to Wisconsin. The boiler has now joined the running gear at SPEC Machine outside Middleton, Wis., where the locomotive will be reassembled.

The boiler left St. Louis on a truck last night and arrived at SPEC Machine around 2 AM today (September 26, 2019). Crews from SPEC Machine, Ideal Crane, and Mid-Continent Railway Museum’s #1385 Task Force volunteers worked together this morning to safely lift the 41,000 lb. boiler from the trailer onto the locomotive frame. Work wrapped up around 2 PM this afternoon.

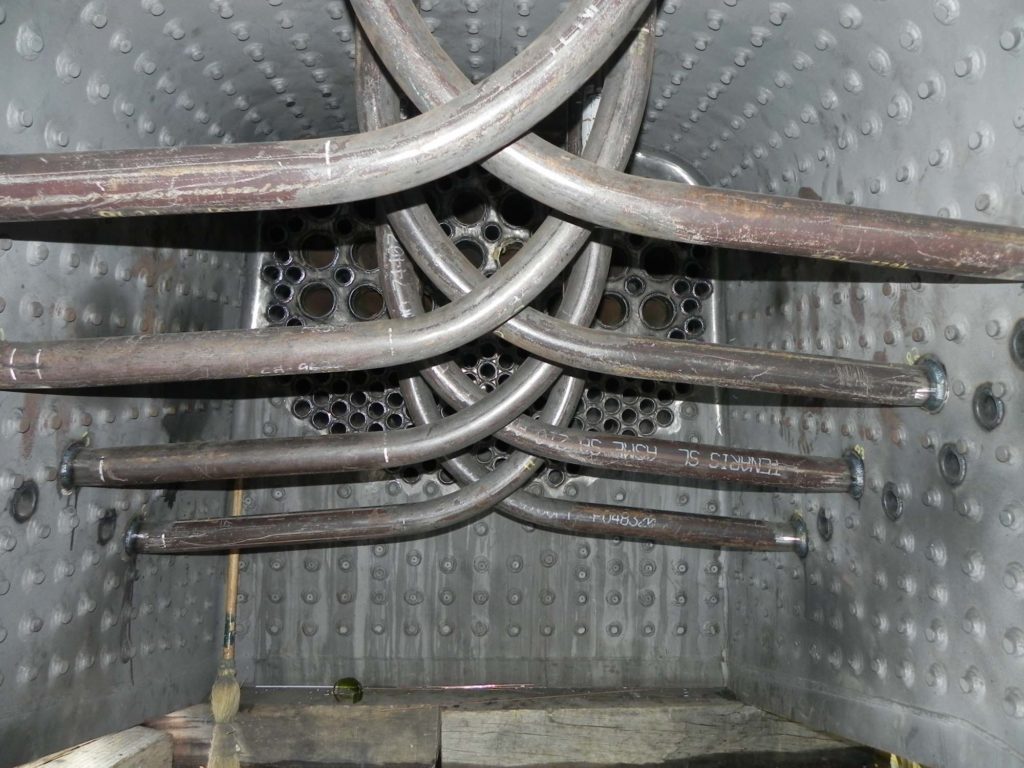

We took lots of photos and video and will share a more complete account of the day’s activities along with video in the next day or two once we’ve had an opportunity to edit it all together. In the meantime, here are a few quick photos from today’s activities.

- Crews prepare to unload 1385’s boiler at SPEC Machine. Jeffrey Lentz photo.

- A 100-ton crane lowers 1385’s boiler onto the frame. Jeffrey Lentz photo.

- 1385’s boiler rests on the frame and the locomotive is readied to roll inside the shop where further reassembly will continue. Jeffrey Lentz photo.

- By the end of the workday, the 1385, now with boiler, was rolled inside a shop bay at SPEC Machine that was specially built for to accommodate the 1385’s reassembly. Jeffrey Lentz.

**PLEASE NOTE**

We appreciate the public’s enthusiasm to see the 1385’s progress first-hand; however, the contractor shops where the #1385 work is taking place are private property and not open to the public. Anyone requesting to see the locomotive at those locations will be turned away. Please help #1385 return to operation as expeditiously as possible by respecting our contractors’ wishes.