Introduction

Good progress continued to be made on the DULUTH project in 2022 thanks to a crew of volunteers, hired help, contractors (for stripping, stained glass, brass polishing and woodworking) and many donors. A total of $29,650 in donations was received this past year, with the largest amount coming from the Emery Rail Heritage Trust grant ($15,000).

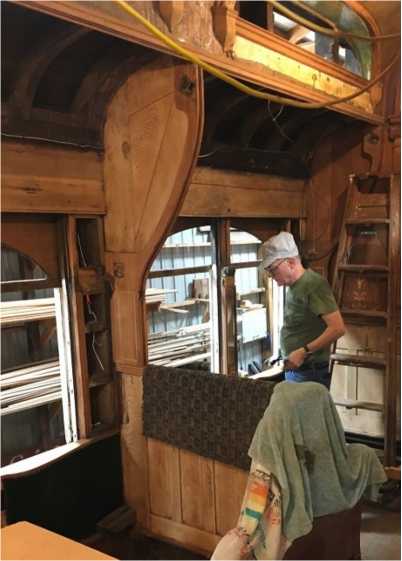

Stripping off the old varnish and paint finishes on the interior woodwork and vestibules was completed this year, while demolition and removal work continued. In addition to the work on the car, a big push was made this year to purchase and line up materials and restoring parts needed for completing the car. We are now starting to see new parts and pieces going back onto the car.

The main emphasis inside the car continues to be working on restoring the 10-section sleeping compartment that is the middle of the car. In this portion of the car new wiring has begun to be installed for both the berth lights as well as the annunciator system. In addition, new headlining panels were made and several of them were installed in the sleeping compartment.

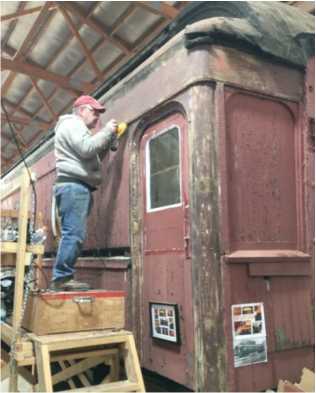

On the exterior of the car much of the old siding has been removed and we have installed a small section of new siding. In addition, removal of the old roofing is complete while the clerestory side framing removal continues. The upper and lower roof boards are in very good condition, only needing a few localized repairs.

Work on the DULUTH will resume in 2023 with a concentration in the sleeping compartment.

Photos and additional information on the progress made during 2022 on the DULUTH Project follows.

Planning

- Updated 3-year restoration plan

- Updated the list of the sleeping compartment work tasks and sequence of activities

- Obtained proposals for reproducing additional wood parts for the car

- Developing and submitting grant requests for 2023

Design Work

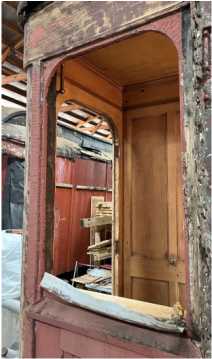

- Measured and designed the (4) vestibule doors and end windows

- Acquired samples of the curved upper drip rails (the end drops)

- Measured and finalized the design for the (3) missing interior doors

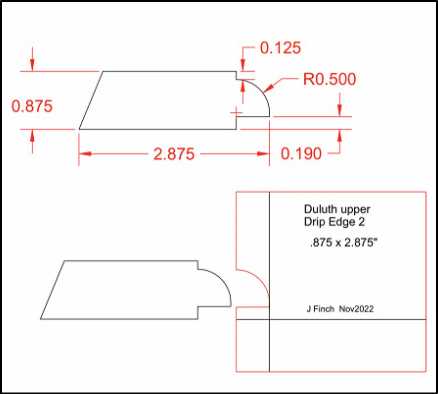

- Designed the upper and lower roof drip edge moldings

Disassembly Work

- Removed the balance of the old roofing material from the roof

- Removed the clerestory wall coverings and roofing on the east side

- Removed the original lower car siding of the entire car

- Removed arched window trim (exterior) and battens

- Removed the intermediate window stops

- Exposed the framing in the NE end vestibule window opening to expose the original window frame

- Removed the (4) vestibule doors from the car

- Removed the hardware off of the (4) vestibule doors

- Removed the seat cushions from the sleeping compartment and put them into storage

Stripping

- Stripped the old finish off of the end vestibules (interior), Women’s room and north aisle. This completes stripping of all of the old finish off of the entire interior of the car.

- Stripped the paint off of the entire letter board

- Stripped the paint off of the arched window frames

- Stripped the old finish off of the headliner trim pieces

- Removed straps and hinges from upper berth racks

- Stripped the old finish off of the upper berth racks

- Removed all of the inner window frames (25) and sent them out for stripping

- Sent out the berth headboards for stripping

- Sanded the lower sides of the car (exterior) to remove the old glue off of the wood framing

Restoration Work

Installation and Painting

- Repaired (7) of the lower roof carlines

- Cut, fit and glued new car siding on the west side of the car (north end). The section of siding consisted of approximately four feet of the car side.

- Installed a new vestibule ceiling panel in the SE corner of the car

- Cleaned, primer and painted the iron work (truss rods, queen posts, etc.) under the car

Materials

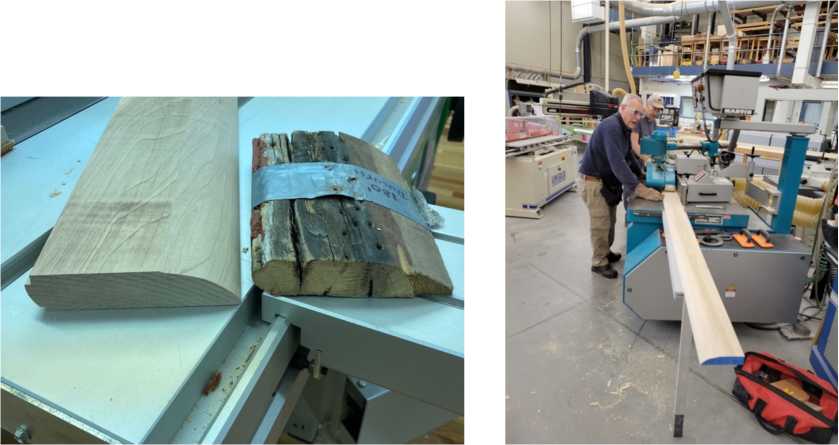

- Ordered replacement specialty wood parts for (window trim, veneer panel, etc.)

- Test fit the berth divider trim piece in the sleeping compartment

- Received specialty wood parts made including the clearstory window frames, trim, battens, veneer panels, berth divider trim pieces, etc.

- Sent out a vestibule door and other wood samples to woodworking shop for replicating the new parts (2023 delivery).

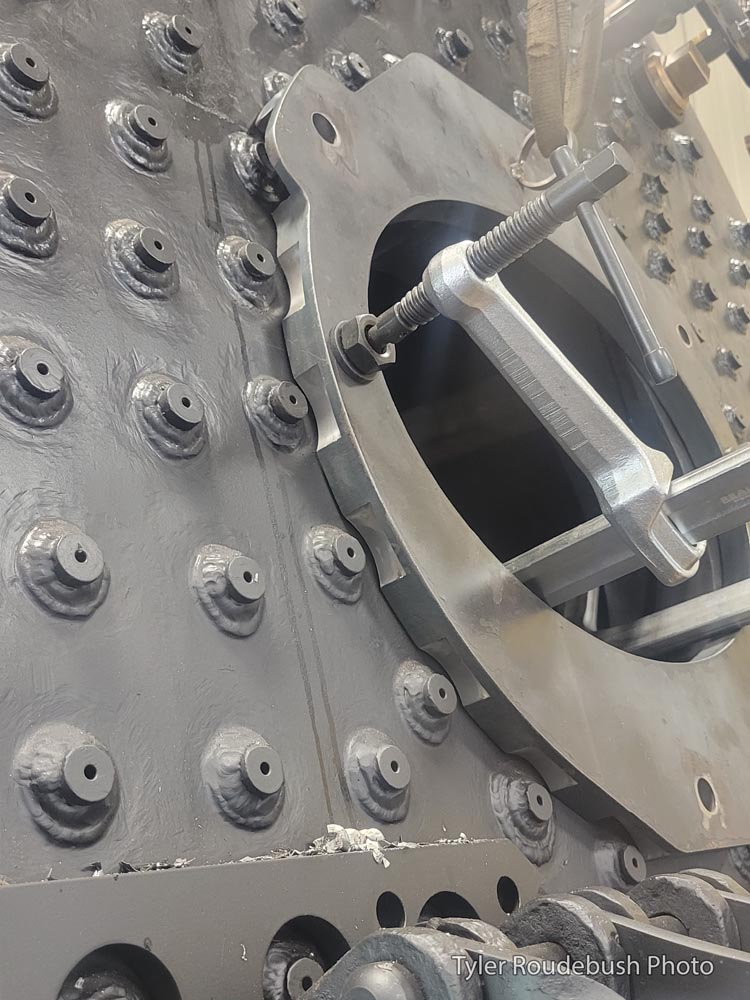

- Purchased poplar material for the upper and lower drip rails

- Milled the new upper (inner) and lower drip rail stock

Parts and Hardware

- Cleaned and polished brass hardware for the sleeping compartment of the car. Presently 99% of the berth and sleeping compartment hardware has been obtained, reconditioned and restored.

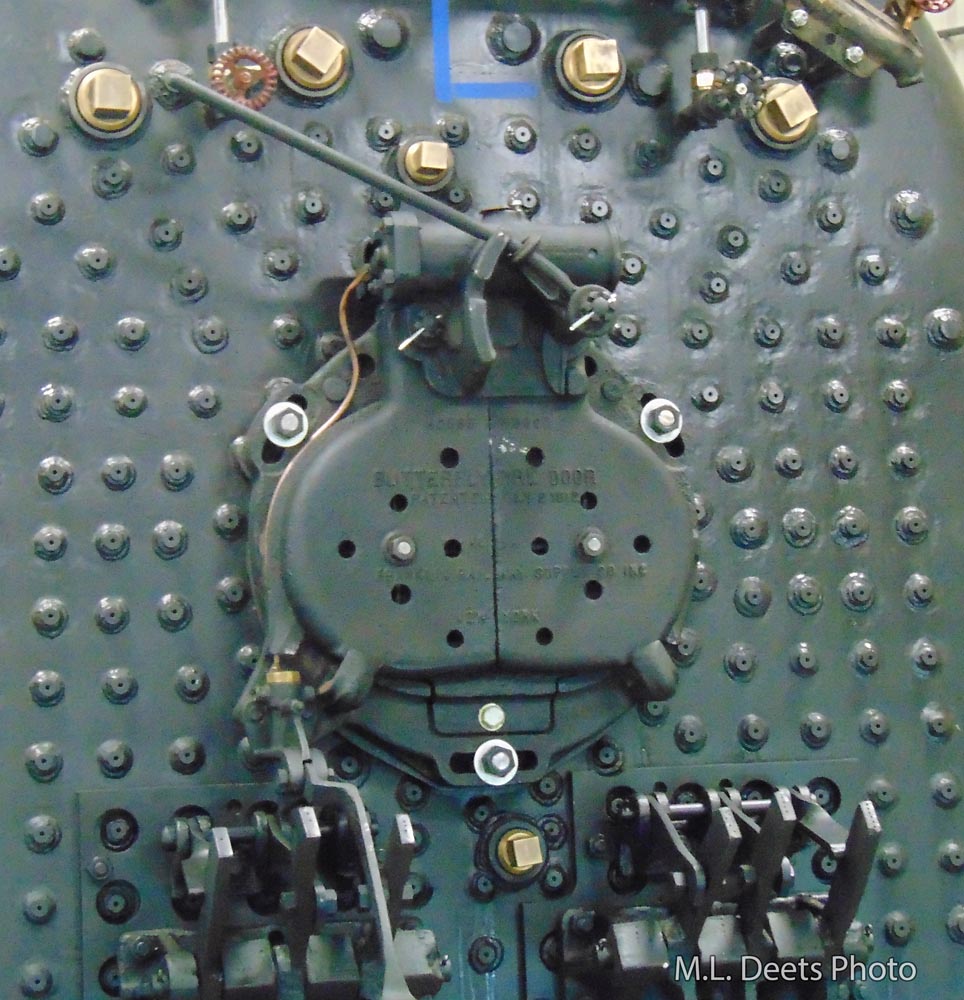

- Restored (4) toilet room roof vents for the DULUTH

- Fabricated a new stack cover for the Baker heater

- Restored and polished the (20) berth dampers

- Stained and varnished the wood plunger blocks for the berths

- Fabricated (6) new steel berth cushion support straps

- Made replica berth curtain rod end supports (12) and curtain rods (6)

- Restored the berth ladder for the car

- Cleaned and polished coach lamps and associated parts (in process)

- Acquired one of the overhead entryway oil lamps for the car

- Stripped the paint off of the vestibule door hardware

- Stripped the brass window catches (100) needed for the car

- Sent out the wooden berth racks (10) and the (8) headboards for finishing (in process)

Wiring

- For safety and reliability purposes the entire car is being rewired. This includes the wiring for all of the interior car lighting as well as the low voltage annunciator system.

- Removed wall trim around the berth lights to access the wiring

- Removed all of the existing wiring in the sleeping compartment

- Installed new wiring for the sleeping compartment berth lamps (Qty. 20). (In process)

- Installed new wiring for the sleeping compartment annunciator buttons (in process)

Stained Glass

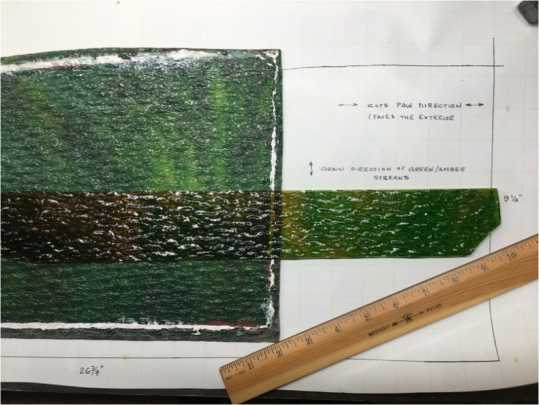

- New stained glass material (sheets) from Kokomo Glass were received for the lower arched and oval windows

- Took receipt of the new stained glass that was cut to size for the lower arched windows

- Temporarily fit two new pieces of stained glass in the arched window frames

- Provided the stained glass shop with oval window frames so the new stained glass can be made to fit into the oval windows (2023 delivery)

Headliners

- Cut the plywood to size for the headliners

- Cut the canvas to size and glued the canvas to the sleeping compartment headliners

- Painted the only remaining (original) headliner (#10) in the sleeping compartment

- Painted the new headliner panels (#1-9). (in process)

- Installed the headliner panels in the car. (in process 4 of 9 installed)

Fundraising

- $29,650.65 in donations were received in 2022. The largest donation came from the Emery Rail Heritage Trust grant ($15,000).

- The “Giving Tuesday Fundraising Challenge” was met by successfully matching the $1200 challenge, in turn raising a total of $2400 for the DULUTH project.

Expenses

| Contract work | $25,937.62 |

| Labor | $6,945.83 |

| Supplies | $2,456.00 |

| Freight | $187.34 |

| Total Expenses for 2022 | $35, 526.79 |

Volunteers

- In 2022 over (20) MCRM volunteers logged (555) man hours of time on the DULUTH project.

Publicity and Events

- A film crew from TRAINS magazine was on hand in the Duluth to perform a Trains LIVE video production. The crew filmed inside and outside the car while commentator Bob Lettenberger discussed the history of the car and the restoration process.

- The DULUTH was opened up for tours in MCRM’s Car Shop during MCRM’s annual Vintage Rail Car Tours.

- The DULUTH project was featured in the September 26th edition of the Baraboo Newspaper.

William Buhrmaster

MCRM Restoration Department

December 22, 2022