The rebuild of the Chicago & North Western steam locomotive is in full swing as of the start of 2015. There are a number of sub-projects at various stages of progression all happening simultaneously involving the frame, driving boxes, wheels, cab and boiler. This post will cover the frame, but additional posts covering other aspects will be posted in the following days and weeks.

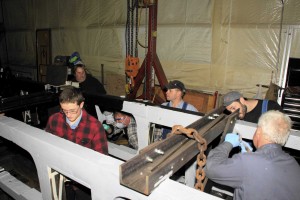

Painting of the frame began on January 2, 2015 and is continuing on January 3rd as this post is being written. Mid-Continent volunteers were joined by Tom Hartling of Howard Grote & Sons, a Madison-area company specializing in protective coatings. Howard Grote & Sons volunteered to provide Mid-Continent with Hartling’s expertise in mixing and applying the epoxy primer and urethane topcoat paint used (Carbothane 134 for those interested).

Work started at about 7 AM on Friday the 2nd, with the first of two coats of primer, the first being black in color. After a break for lunch, the second coat, gray in color, was applied with work mostly wrapping up by 4:30 PM. Application of the topcoat was left for Saturday January 3rd.

Work on Friday went quickly thanks to an enthusiastic response by volunteers. Mid-Continent volunteers joining in on Friday were: Mike Wahl, Pete Deets, Ron Kokemuller, Jeff Huttenburg, Bobbie Wagner, Kyle Gherke, Robert Hasheider, Mike Laabs, Larry Stanley, Rich Gruber, Brian Allen, Al Joyce, and Jeffrey Lentz. These MCRM members were also joined by Steve Roudebush (of SPEC Machine), Kayla Roudebush, and Clayton Hendrickson.

Nearly 100 additional photos of the January 2nd workday are available on photographer Brian Allen’s Flickr photo album. The video below is a one-minute timelapse showing the roughly three hours of work adding the second coat of primer.

[youtube]BQLRCr6R9_M[/youtube]