We are very pleased to announce that Mid-Continent Railway Museum has received a $15,000 grant from the John H. Emery Rail Heritage Trust (ERHT) for use on Mid-Continent’s Duluth South Shore & Atlantic sleeping car “DULUTH”.

The DULUTH was built in 1902 by the Barney & Smith Car Company. The 10-section sleeping car operated daily on the DSS&A’s passenger train between Sault Ste. Marie, MI and Duluth, MN until 1934. After the car was taken out of service it was sold to a private resident of Laurium, MI and it spent the next 81 years as a summer cabin on the shore of Lake Superior. In 2015 the car was donated to MCRM and in 2016 the DULUTH was moved to the MCRM, where restoration work began to return the car to its original configuration and operating condition. For additional historical information, see the DULUTH’s Roster Page.

Much work has been done to date to restore the car. To date, volunteers and employees have dedicated a combined 3,200+ hours working on the DULUTH. This 2022 grant from the ERHT will enable MCRM to focus on the sleeping compartment, making new stained glass windows and performing some exterior work. Once this phase is completed, restoration of the car’s other interior sections, seat upholstery, carpeting and the exterior restoration will take place as separate phases of the whole project.

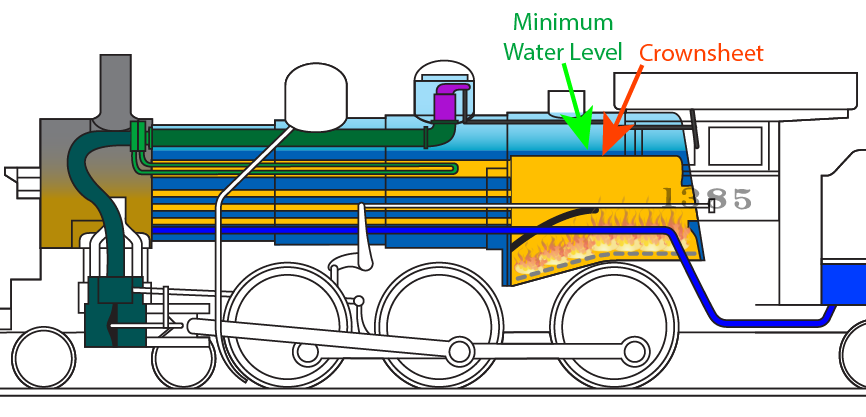

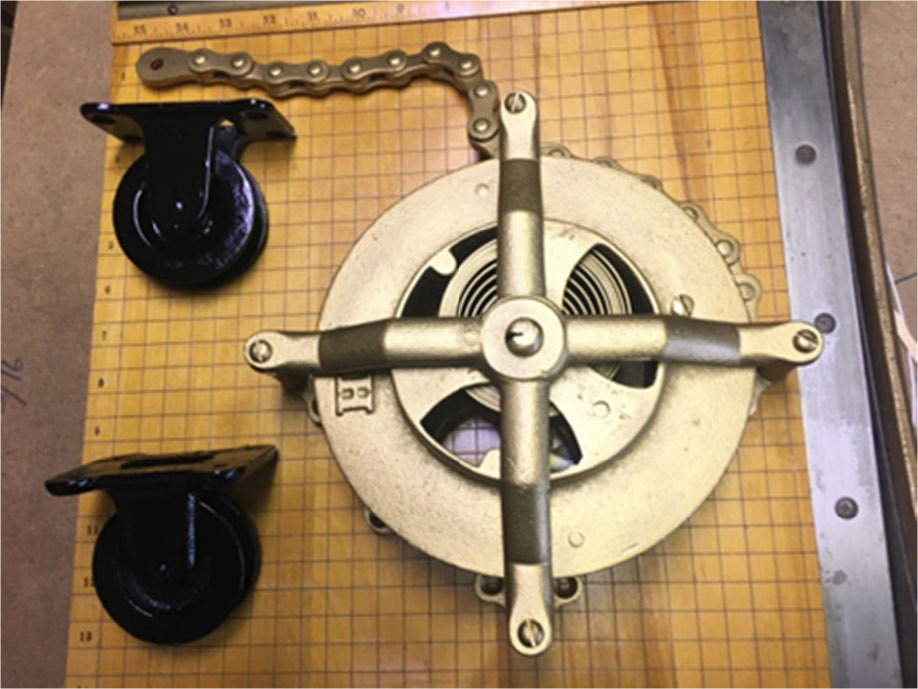

This is the second grant the John H. Emery Rail Heritage Trust has awarded to the DULUTH project. The Trust previously awarded $9,000 for the DULUTH in 2018 and has supported other museum projects as well, including the C&NW #1385 steam locomotive and the museum’s DL&W #595 coach car. Mid-Continent Railway Museum sincerely thanks the John H. Emery Rail Heritage Trust for their most generous grant.

About the John H. Emery Rail Heritage Trust:

The John H. Emery Rail Heritage Trust was created by John Emery, a native of Chicago, and a lover of the classic passenger trains of America. The Trust was founded as a way to support Mr. Emery’s interests in the passenger trains of the 1920s through the 1950s. The Trust operates as a tax-exempt 501(c)(3) foundation