Since we have a new month and new Monday we also have a new update! Tom G. from Continental Fabricators writes:

Here is the latest update..

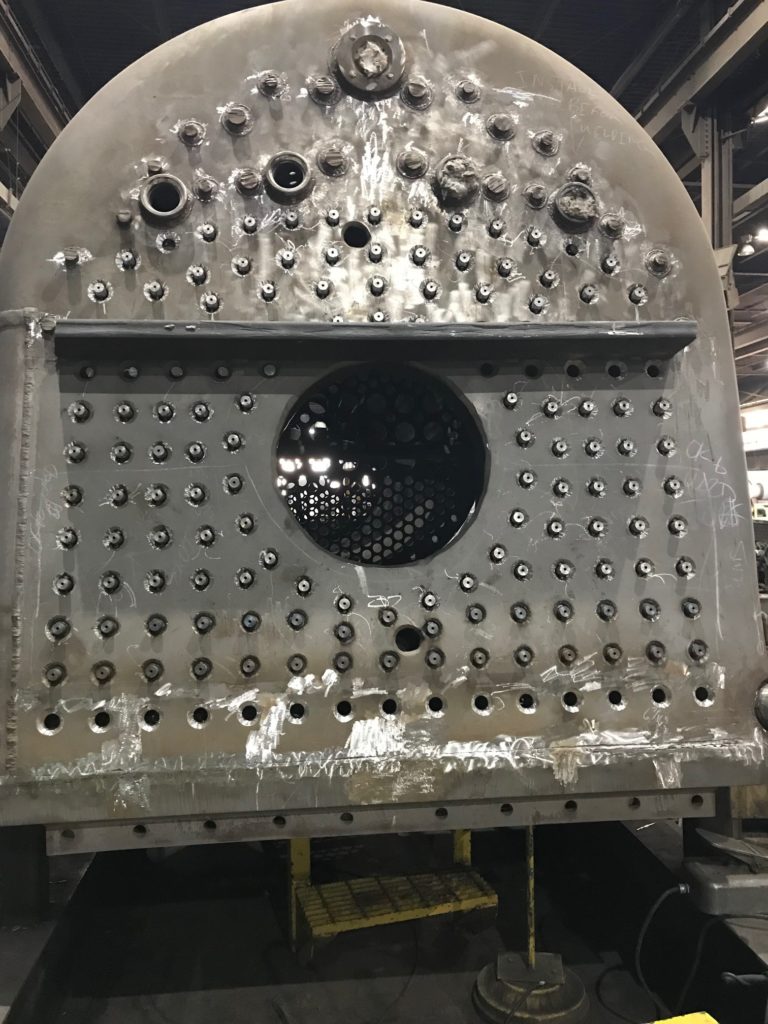

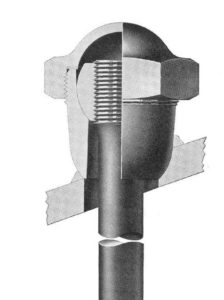

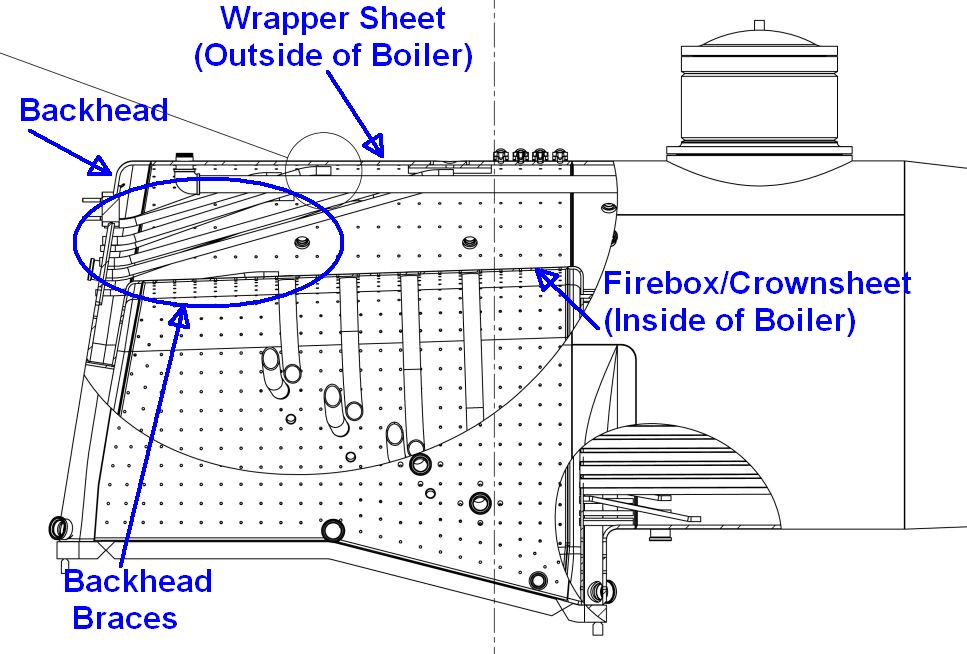

All but 22 backhead stays are installed, most of them have the root pass in and working on completing the welding.The side sheet stays are also moving along.

Throat sheet flexible stay installation to start this week…

Included with the update was two photos.

- Welding for all but 22 of the backhead stays is complete in this photo dated May 6, 2019. Courtesy Continental Fabricators.

- Progress on welding the sidesheet stays can be seen. May 6, 2019. Photo courtesy Continental Fabricators.