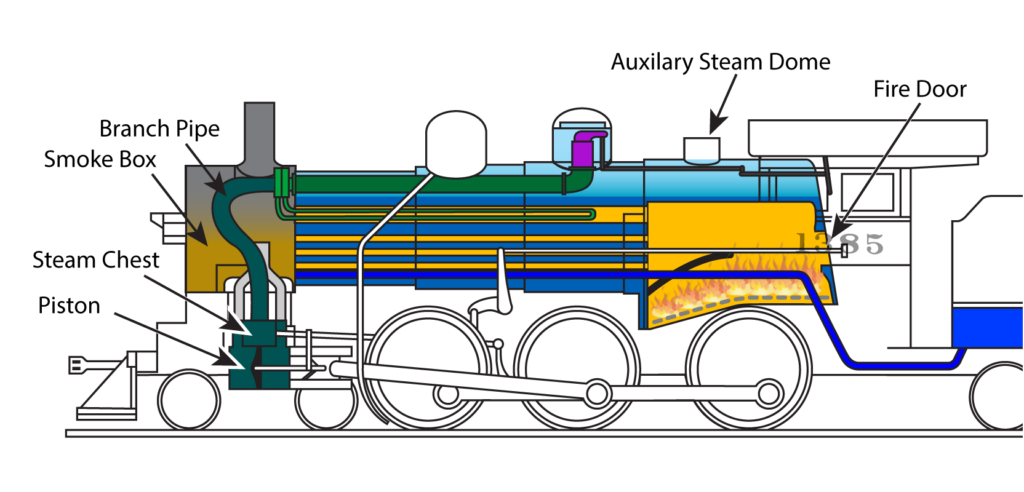

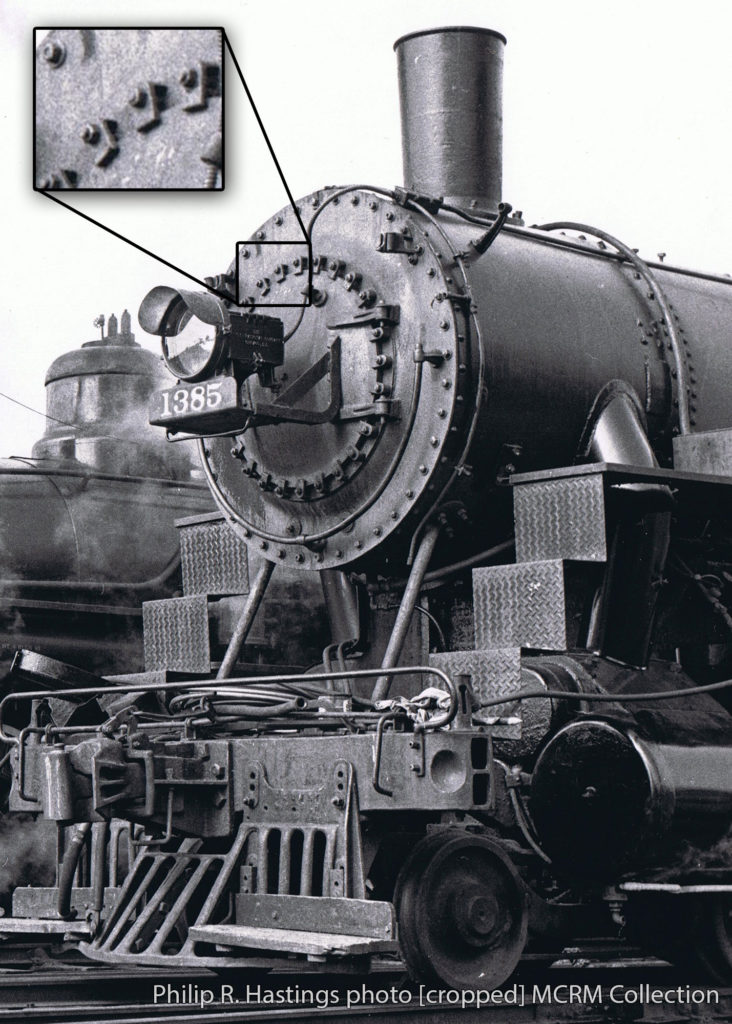

When it comes to the proper operation of a steam locomotive there is no minor detail. Every piece must perform properly. That extends all the way to the clips or “dogs” that hold the door shut on the front of the smokebox. You may ask why and I hope to explain.

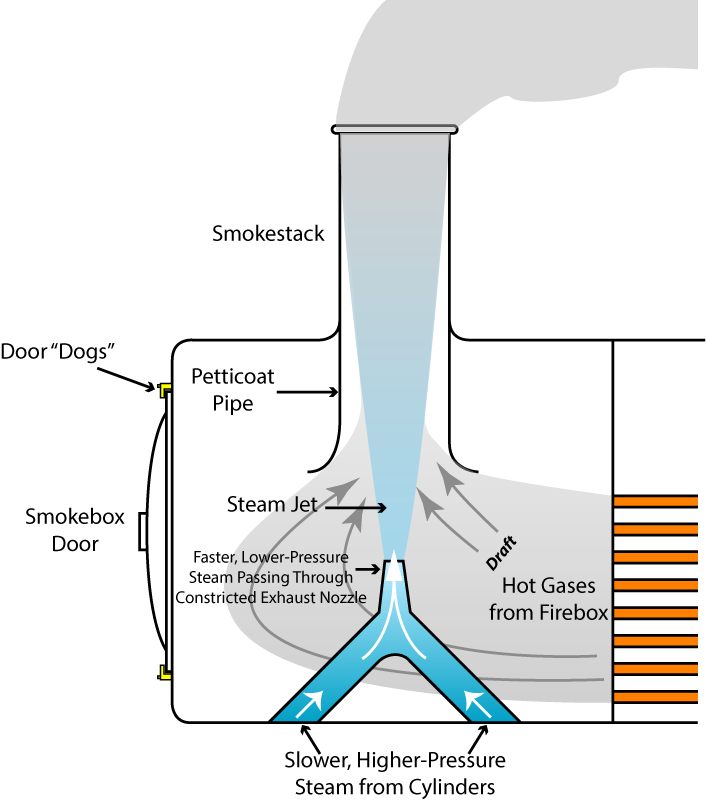

First and foremost to work efficiently a locomotive must generate steam well and in great quantity. One of the factors that figure heavily is how much air is drawn through the fire to ensure plenty of oxygen to support the combustion of the fuel. That air is drawn by the creation of a partial vacuum in the smokebox of the engine. That partial vacuum is created by directing the exhaust steam from the cylinders up through the exhaust nozzle and into the petticoat pipe at the base of the smokestack. The exhaust is moving at a very high speed and because there is an open space between the nozzle and petticoat and due to the shape of both devices it will pull some of the gases in the smokebox along with it up and out the stack.

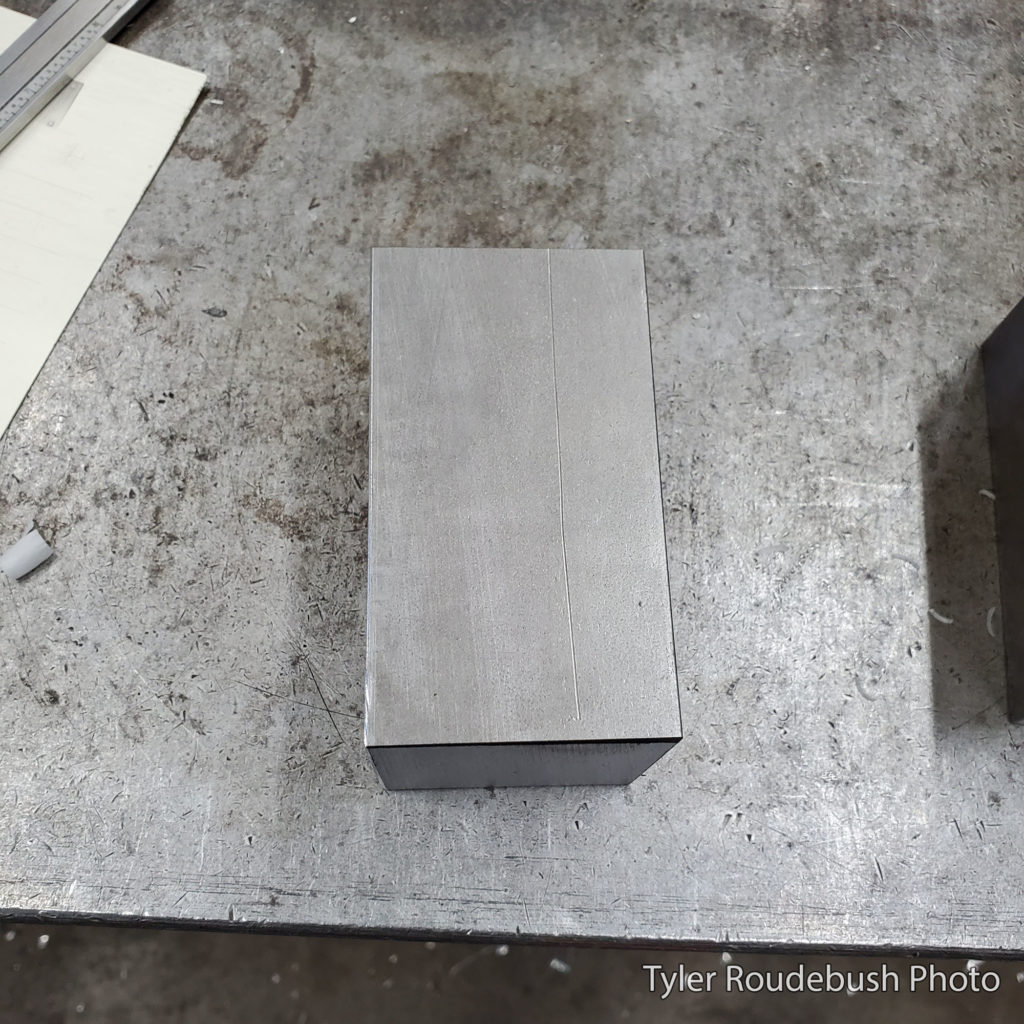

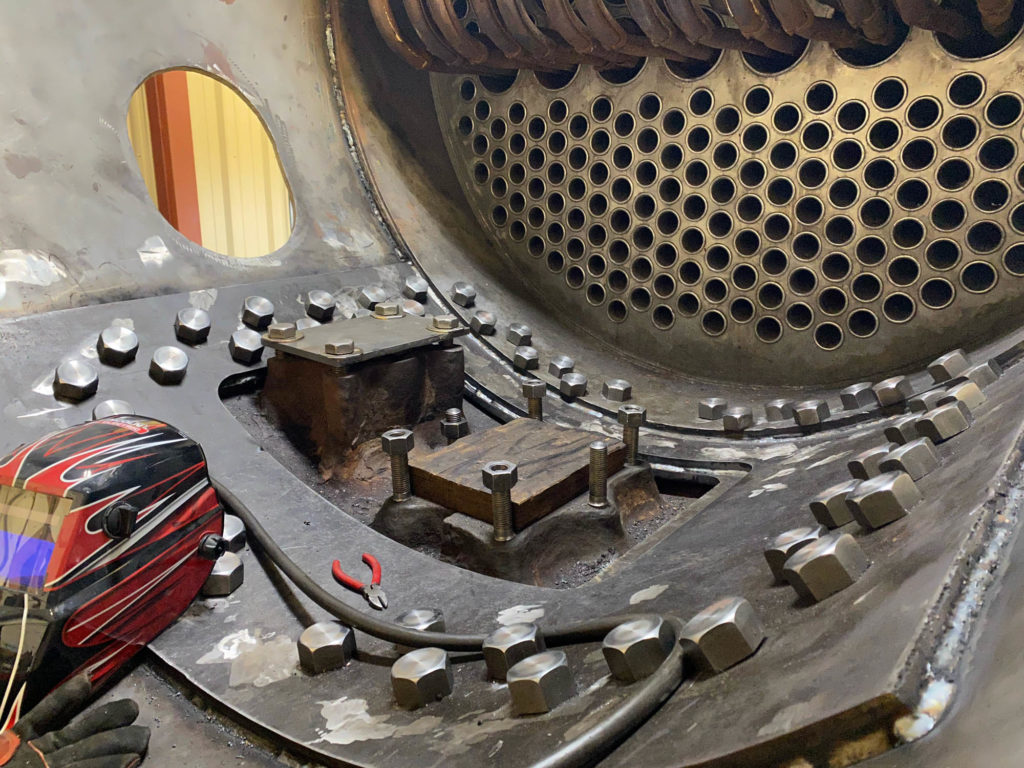

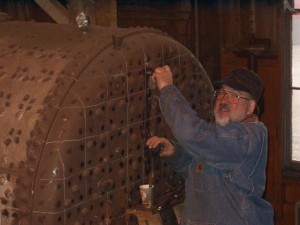

Mother Nature is always following the path of least resistance so if there is a vacuum leak around the smokebox door air will be drawn in from there first rather than the more difficult path of up through the fire bed and down the tubes & flues to the smokebox. If there is a leak at the door the engine will not steam well and efficiency suffers. This is why the door dogs are important in that they must clamp the door down evenly on the gasket all the way around the edge in order to get a good vacuum seal. Having the dogs a uniform size & shape makes it easier to judge when each has been properly tightened down.