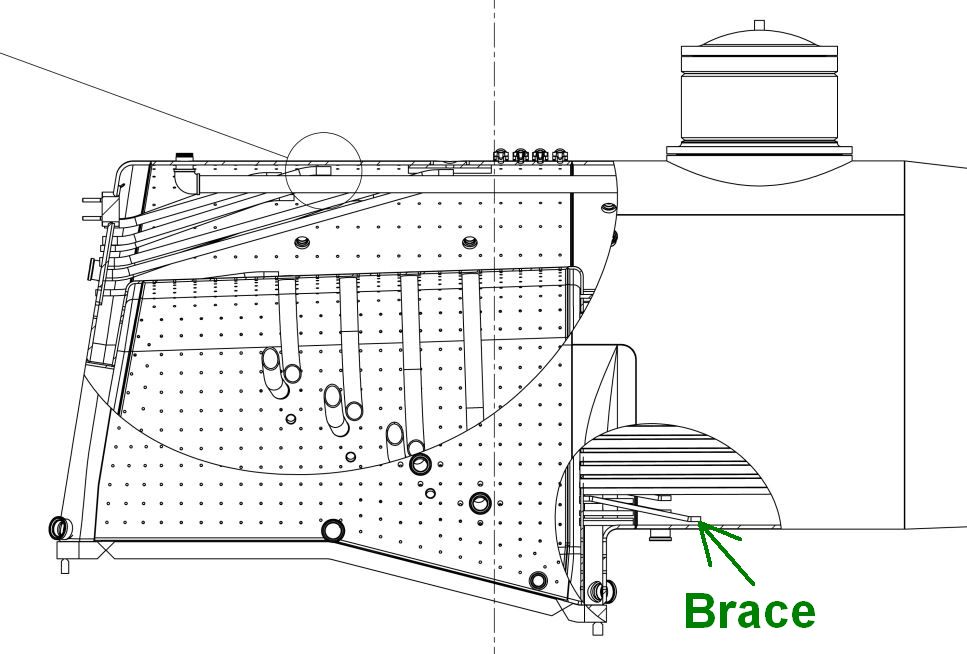

Work continues at SPEC Machine in Middleton which includes creating a new lubrication system for the main axle journals on our engine. The Chicago & North Western’s drawings give specifications for either using oil or hard grease on the axles and as the 1385 came to us the engine used hard grease. As the serious running gear work was begun, the decision was made to convert the journals to oil lubrication. The largest change necessary was to design and build oil cellars to replace the grease cellars that had been used previously.

-

-

-

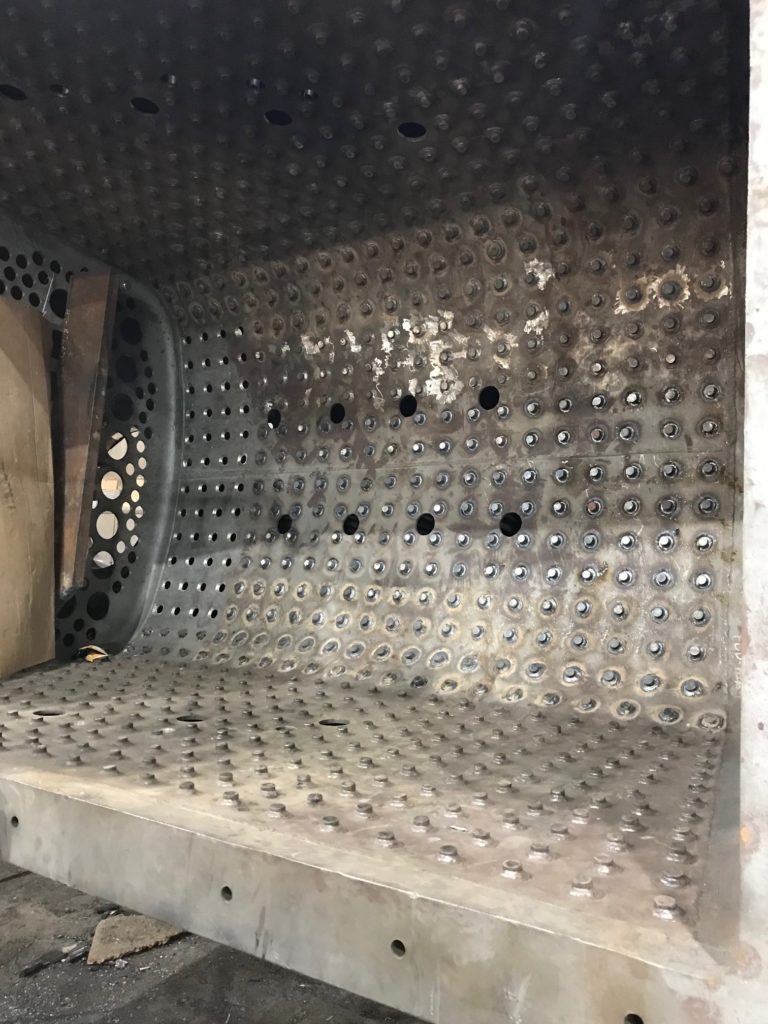

Grease cellar from 1385.

The first picture shows old and new side by side. The next picture shows the simple box the grease cellar is. It is shaped to hug the axle to keep big chunks of ballast out and the holes in the bottom are there to allow the indicator chains to hang down to give the servicing crew an idea of how much grease was left in the cellar. While it works well in this service it won’t hold much oil for very long. To use oil you need a sealed box to hold some extra oil to constantly feed the lubricating pad that will be pressing up on the journal.

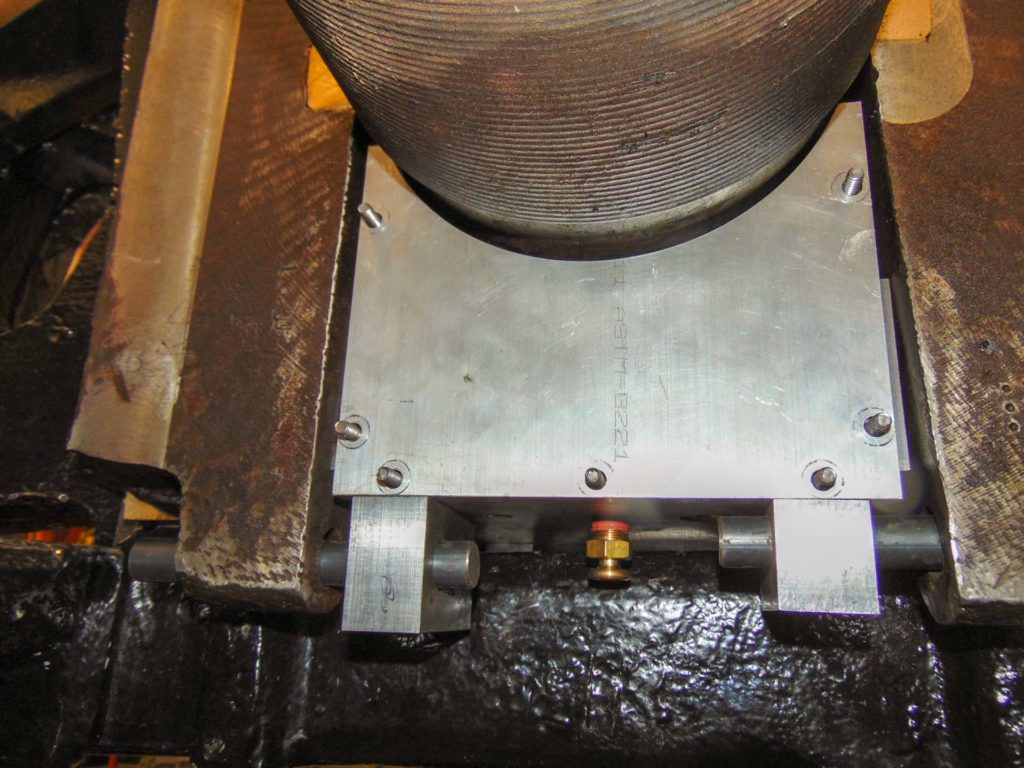

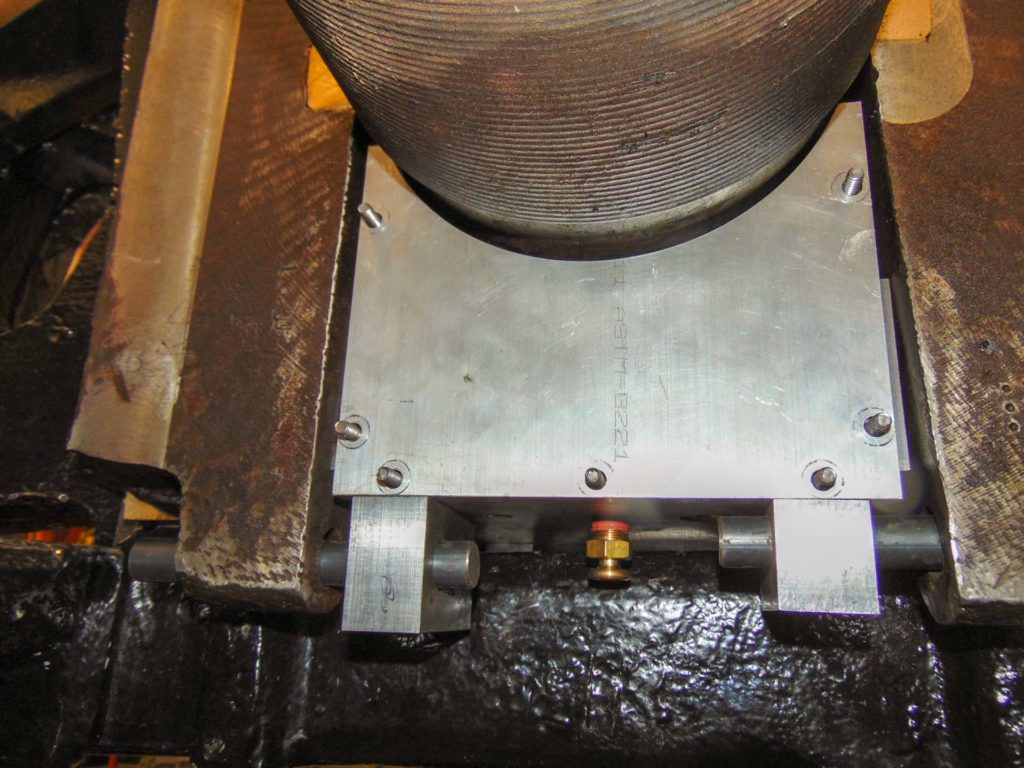

Shown below on the bottom of the oil cellar from left to right are a drain plug, the water drain/oil fill port and the plug for the oil level standpipe. The eight small holes are there for the mounting bolts that will attach the mounting lugs to the bottom of the cellar.

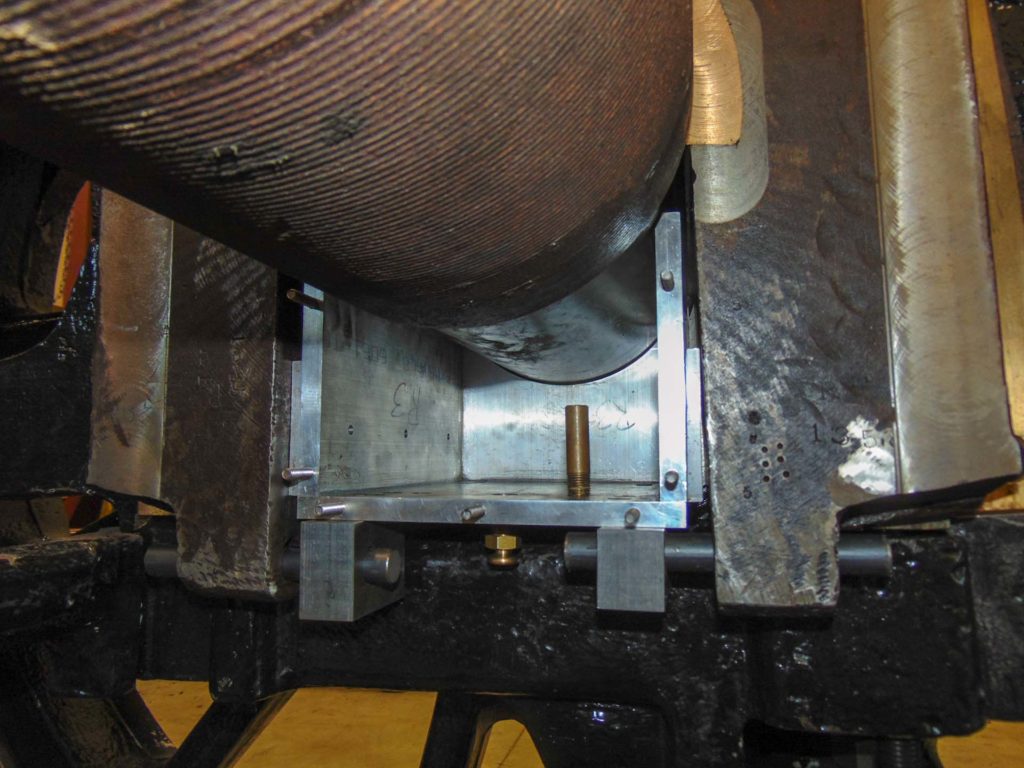

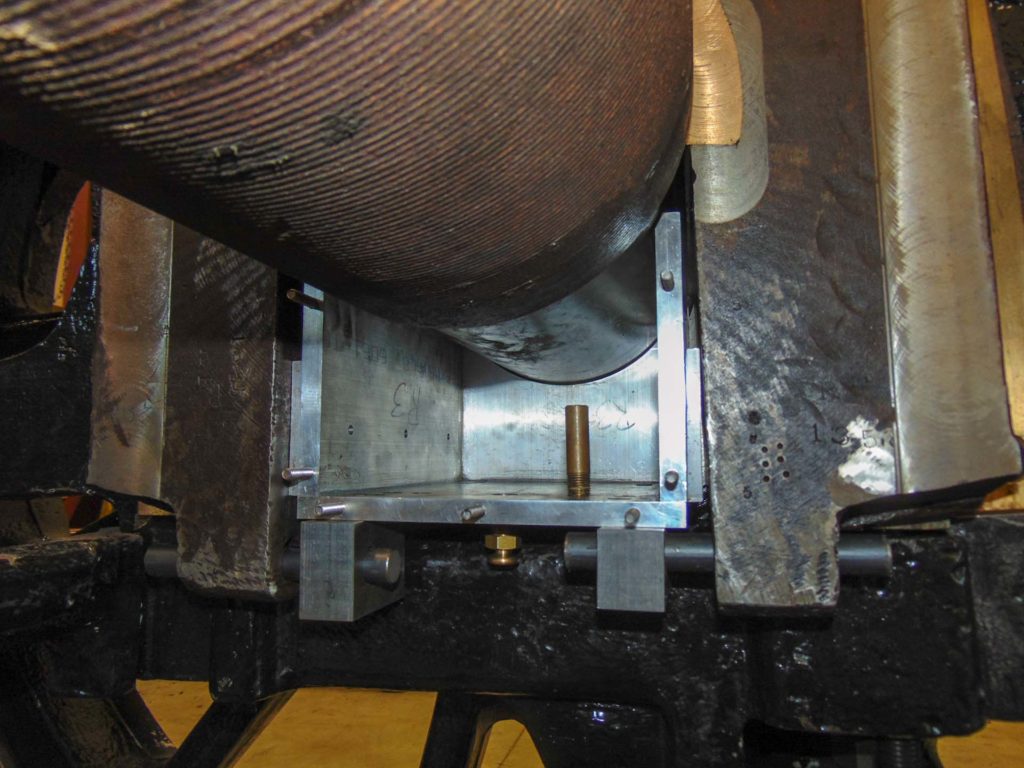

The next shot shows the cellar in place below the axle and in the bottom of the driving box.

The next picture shows how “form-fitting” the cellar is in following the shape of the axle.

The next picture shows how “form-fitting” the cellar is in following the shape of the axle.

With the end cover removed you can see the oil level standpipe standing up into the oil space. Once we receive the custom made pads from Armstrong they will also tell us where the oil level should be kept while the engine is in service. Knowing that we will cut off the standpipe to the proper level to indicate when the cellar is full.

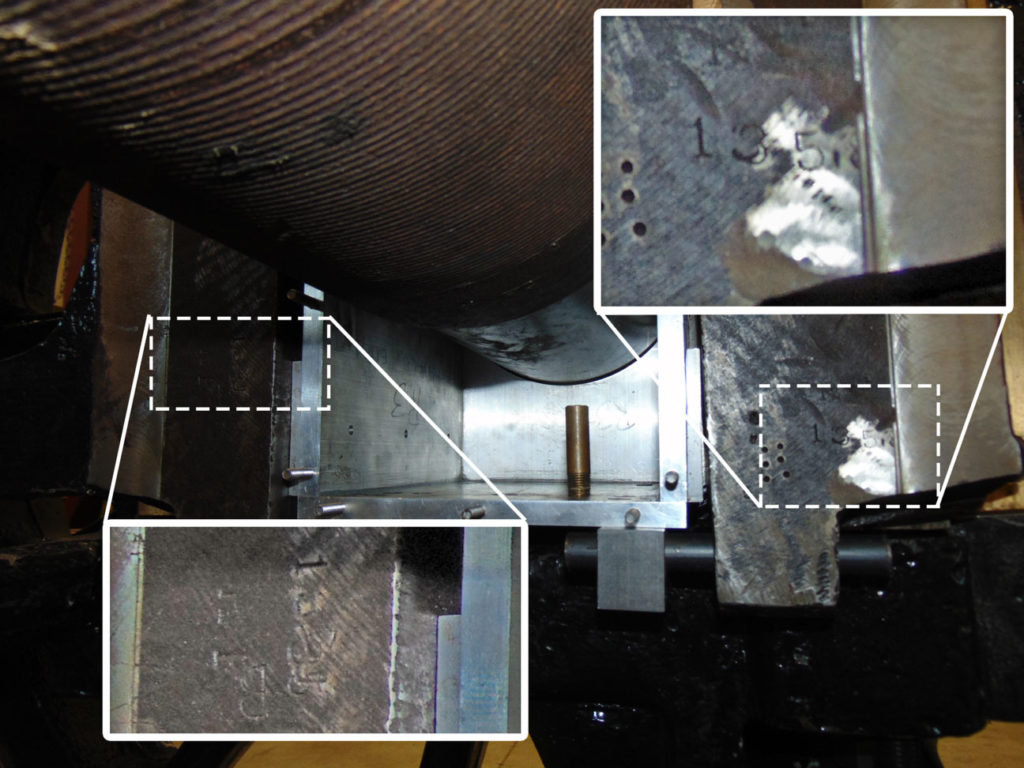

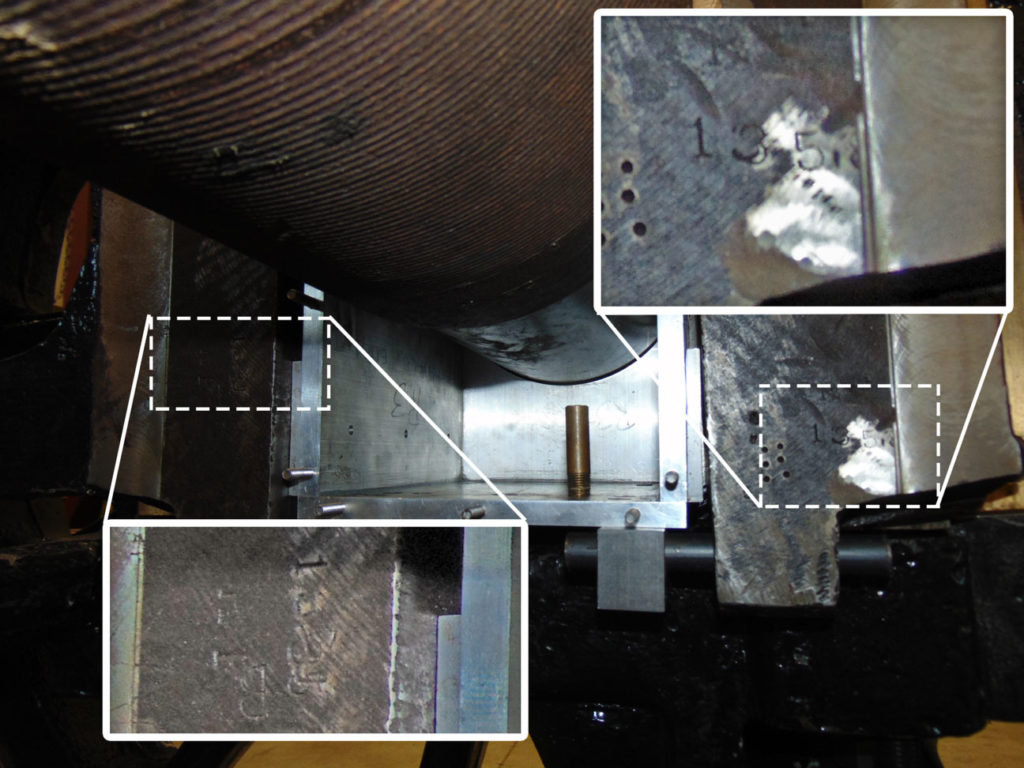

The C&NW’s history of frugality earned it the nickname the “Cheap & Nothing Wasted.” It is easy to see how that nickname came about when you see things such as the engine number 135 stamped on the right-hand jaw of the driving box next to the machined surface. On the other jaw is stamped 1385. The photo above is repeated below with the stamped text enlarged for easier viewing. Even years ago the railroads practiced recycling and “repurposed” useful parts to keep the R-1 fleet running.

As a reminder, SPEC Machine is a private facility and the 1385 is not accessible to the public nor open for tours. We are looking forward to showing off the 1385 to everyone upon its return to Mid-Continent Railway Museum.